You can achieve outstanding purification results in your industrial processes with PTFE Membrane technology. Just look at this data:

| Membrane Type | Filtration Efficiency |

|---|---|

| PTFE (Zhong et al.) | > 99.9999% dust removal |

| PTFE (Xu et al.) | > 99.99% for particulates |

PTFE Membrane stands out for its durability, chemical resistance, and ability to handle tough environments, giving you cleaner air and water every time.

Key Takeaways

- PTFE membranes offer exceptional chemical resistance, thermal stability, and hydrophobicity, making them ideal for tough industrial air and liquid purification tasks.

- These membranes provide high filtration efficiency and durability, reducing maintenance needs and downtime while ensuring cleaner air and water.

- PTFE membranes work across many industries, helping companies meet strict environmental standards and improve process reliability with long-lasting, cost-effective solutions.

PTFE Membrane Unique Properties

Chemical Resistance

You can trust PTFE membranes to stand strong against the harshest chemicals. Their unique carbon-fluorine bonds give them unmatched resistance to aggressive solvents, acids, and bases. This means you can use them in environments where other materials would quickly break down.

Tip: PTFE membranes work well in pharmaceutical and chemical processing, where chemical exposure is constant.

| Property | PTFE Membranes | Cellulose Acetate Membranes |

|---|---|---|

| Chemical Resistance | Unparalleled resistance to aggressive solvents, acids, and bases | Significantly lower chemical resistance; suitable mainly for mild chemical environments |

| Application Suitability | Ideal for harsh chemical and industrial environments | Suitable for aqueous and mild chemical environments |

Hydrophobicity and Oleophobicity

You benefit from the natural hydrophobic and oleophobic properties of PTFE membranes. Water and oil simply cannot penetrate the surface easily, which helps prevent fouling and keeps filtration efficient. When you use PTFE membranes, you experience less downtime for cleaning and enjoy longer-lasting performance. Scientific research shows that these membranes can even be modified to further boost their anti-fouling abilities, making them a smart choice for challenging filtration tasks.

Thermal Stability

You can rely on PTFE membranes to perform across a wide temperature range. They stay stable and effective from 17°C up to 80°C, and some specialized types can handle even higher temperatures. This flexibility allows you to run purification processes without worrying about membrane degradation.

Note: PTFE membranes maintain their structure and filtration ability even when temperatures fluctuate, giving you peace of mind in demanding industrial settings.

Controlled Pore Size

You gain precise control over what passes through a PTFE membrane. Manufacturers can tailor the pore size to your needs, ensuring high selectivity and efficiency.

- PTFE membranes with pore sizes up to 0.45 μm keep contaminant removal rates high.

- Larger pores increase flow rates without sacrificing much efficiency.

- Special composite designs can filter out nanoparticles as small as 7–16 nm, combining high selectivity with fast processing.

Mechanical Strength and Durability

You can count on PTFE membranes for long-term reliability. Their strong structure resists wear, pressure, and chemical attack. Some PTFE membranes last up to 30 years, even in tough industrial environments.

- They withstand extreme temperatures and weather.

- Their non-stick surface reduces fouling and makes cleaning easier.

- Modified PTFE membranes with added fibers show even greater strength and durability, supporting your operations for years.

PTFE Membrane in Air Purification

Dust Collection and Particulate Removal

You can transform your industrial air filtration system with the power of PTFE membranes. Their unique microstructure, made of interconnected fiber-like strands, creates a web that captures even the smallest dust particles. The average pore size of about 1.5 micrometers allows you to trap fine particulates through both diffusion and interception. This means you get cleaner air and a safer work environment.

When you use PTFE membranes, you notice a low initial pressure drop. As dust builds up, the pressure increases slowly and predictably. This helps you save energy and extend the life of your filters. In real-world tests, PTFE HEPA filters only double or triple their pressure drop over time, while other filter types can increase by ten times or more. You gain reliable performance and lower maintenance costs.

Tip: PTFE membranes help you maintain steady airflow and high filtration efficiency, even as dust accumulates. This keeps your operations running smoothly.

Industrial Emissions Control

You play a vital role in protecting the environment when you choose PTFE membranes for emission control. These membranes capture harmful particles like PM2.5 and PM10, as well as volatile organic compounds and acid gases. Their chemical resistance and ability to withstand high temperatures make them perfect for tough industrial settings, such as power plants and chemical factories.

- PTFE membranes work in catalytic converters and flue gas desulfurization systems.

- They help you meet strict environmental standards, including the US EPA Clean Air Act and the EU Industrial Emissions Directive.

- Expanded PTFE membranes offer even greater porosity, boosting your filtration and gas separation results.

- PTFE coatings prevent fouling in heat exchangers, improving fuel efficiency and reducing greenhouse gas emissions.

You can feel confident knowing your filtration system supports compliance with global regulations. This not only protects the environment but also strengthens your company’s reputation.

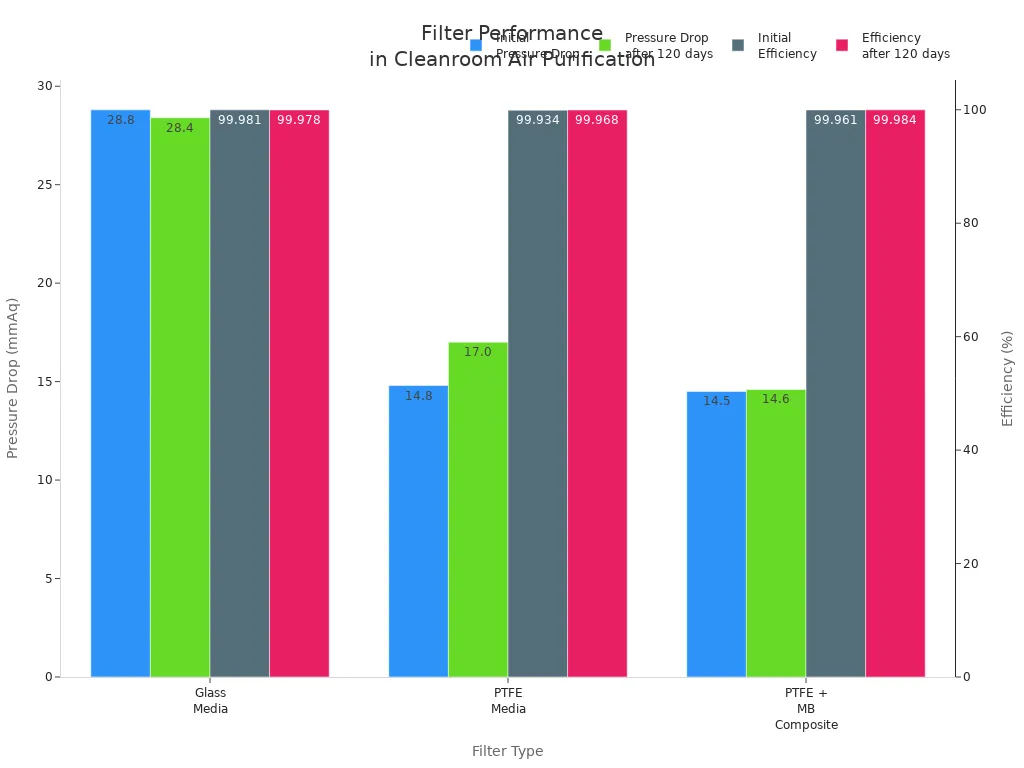

Cleanroom and Sensitive Environment Applications

You can achieve the highest air quality standards in cleanrooms and sensitive environments with PTFE membrane-based filters. These filters deliver exceptional performance in places like semiconductor factories, pharmaceutical labs, and hospitals. They maintain high efficiency while keeping pressure drops low, even after months of continuous use.

| Filter Type | Initial Pressure Drop (mmAq) | Initial Efficiency (%) | Pressure Drop after 120 days (mmAq) | Efficiency after 120 days (%) |

|---|---|---|---|---|

| Glass Media | 28.8 | 99.981 | 28.4 | 99.978 |

| PTFE Media | 14.8 | 99.934 | 17.0 | 99.968 |

| PTFE + Melt-Blown (MB) Composite | 14.5 | 99.961 | 14.6 | 99.984 |

You see these filters in action at leading hospitals and pharmaceutical companies. For example, advanced PTFE membrane filters keep the air pure in bio-pharmacies and nuclear power plants. They also support cleanroom production in the life science and healthcare industries. You can trust these solutions to protect sensitive products and ensure the safety of your staff and patients.

PTFE Membrane in Liquid Purification

Industrial Wastewater Treatment

You can transform your industrial wastewater treatment process with advanced membrane technology. PTFE membranes give you a powerful tool to handle even the most challenging waste streams. Their chemical resistance lets you treat water containing strong acids, bases, and aggressive solvents without worrying about damage or loss of performance. You can operate your system at high temperatures, from freezing cold up to 260°C, and still achieve reliable results.

- PTFE membranes remove more than 99% of contaminants like sulfate, aluminum, and iron.

- You see organic matter removal rates above 85.7%, helping you meet strict discharge limits.

- The hydrophobic nature of these membranes prevents water and contaminants from clogging the pores, so you maintain steady flow and reduce cleaning needs.

- You benefit from long-term stability, with consistent performance over months of operation.

You can rely on PTFE membranes for membrane bioreactors and other advanced treatment systems. Their self-cleaning properties and low friction surface keep your system running smoothly, even when treating highly corrosive or high-temperature wastewater. You create a safer, cleaner environment for your facility and the community.

Removal of Fine Contaminants and Microorganisms

You want the purest water possible for your processes. PTFE membranes help you achieve this goal by trapping even the smallest particles and microorganisms. You can filter out bacteria and submicron contaminants with efficiency rates above 99.99%. This level of filtration protects your products and equipment from contamination.

- PTFE membranes maintain high throughput and low resistance, even at low pressure.

- Their hydrophobic and oleophobic surfaces prevent clogging, so you enjoy stable, long-term filtration.

- You can use these membranes in pharmaceuticals, food and beverage, and chemical processing, where clean water is critical.

You gain peace of mind knowing your filtration system delivers consistent, reliable results. PTFE membranes work in harsh conditions, from below zero to extreme heat, and resist both chemicals and biological fouling. You keep your operations safe and your products pure.

Compliance with Environmental Standards

You face strict environmental regulations in today’s industrial world. PTFE membranes help you meet and exceed these standards with confidence. Their superior contaminant removal ensures your treated water meets or surpasses local and international discharge limits. You can trust these membranes to deliver low sulfate concentrations and high removal rates for metals and organic matter.

- PTFE membranes maintain stable performance over long periods, supporting continuous compliance.

- You reduce the risk of regulatory penalties and protect your company’s reputation.

- Their durability and resistance to fouling mean fewer shutdowns and lower maintenance costs.

You set a positive example for your industry by choosing advanced filtration solutions. PTFE membranes empower you to protect the environment, support your business goals, and inspire others to follow your lead.

PTFE Membrane vs. Conventional Filtration Materials

Filtration Efficiency and Selectivity

You want the best results for your filtration system. PTFE Membrane technology gives you a clear advantage. Studies show that PTFE nanoparticle-decorated filters reach up to 98.79% efficiency for particles between 0.5 and 10 micrometers. This outperforms many traditional filters. The unique 3D microporous structure captures more particles and keeps your air and water cleaner. You also benefit from high selectivity. The controlled pore size and hydrophobic surface let you target specific contaminants, even in tough industrial environments.

| Feature | PTFE Membranes | Traditional Materials |

|---|---|---|

| Filtration Efficiency | Up to 99.9% | Lower, misses fine dust |

| Selectivity | High | Lower |

| Chemical Resistance | Excellent | Prone to degradation |

Operational Life and Maintenance

You can count on PTFE Membrane filters to last longer and work harder. The semi-porous layer on the surface stops dust from getting deep inside, so you avoid filter blinding. This means you spend less time on maintenance and more time running your operations. Replacing these filters is simple. The design allows for quick changes without taking apart complex fittings. You get consistent performance and fewer interruptions.

Tip: Cleaner samples help your PTFE Membrane last even longer. Use a pre-filter for high-solid systems.

Cost-Effectiveness and Long-Term Value

You invest in PTFE Membrane technology for lasting value. While the initial cost may be higher, you save money over time. The durability and efficiency reduce the need for frequent replacements. You also lower your energy use and maintenance costs. PTFE Membrane filters help you meet environmental standards and protect your business reputation. You make a smart choice for your future.

Practical Benefits and Industrial Applications of PTFE Membrane

Enhanced Process Reliability

You can count on PTFE membranes to keep your operations running smoothly, even in the toughest environments. Their chemical resistance and high temperature tolerance let you handle extreme conditions without worry. The porous structure allows high flow rates while still trapping tiny particles, so you maintain product purity and efficiency. Non-stick surfaces reduce wear on your equipment, which means fewer breakdowns and longer service life. When you use these membranes, you boost your production output and improve your overall equipment effectiveness. This reliability helps you meet your goals and inspires confidence in your team.

When you choose PTFE membranes, you create a safer workplace and reduce risks like dust explosions. You also support environmental sustainability by filtering out harmful particles.

Reduced Downtime and Maintenance

You want your systems to work with as little interruption as possible. PTFE membranes make this possible. Their surface filtration keeps pressure loss steady and prevents clogging, so you avoid sudden shutdowns. The microporous design stops dust from getting deep inside, which means you can clean the surface easily—sometimes just by brushing. You also save energy because these membranes work well at low pressure. Their hydrophobic and non-adhesive surfaces resist fouling, so you spend less time on maintenance and more time focusing on what matters most.

Versatility Across Industrial Sectors

You can find PTFE membranes in almost every industry. They help you bake food, seal packages, print textiles, and protect electronics. In the chemical sector, they line tanks and pipes. In aerospace and automotive, they provide heat shielding and insulation. Medical professionals use them in artificial blood vessels and implants. The table below shows just how many ways you can use these membranes:

| Industry Sector | Applications |

|---|---|

| Food Processing | Baking sheets, oven liners, conveyor belts |

| Packaging | Heat sealing, release sheets, packaging lines |

| Textile | Digital printing, drying, lamination |

| Chemical | Gaskets, seals, tank linings |

| Electrical | Wire insulation, circuit boards |

| Aerospace & Automotive | Heat shielding, insulation, composite molding |

| Construction & Architecture | Tensioned membrane structures |

| Industrial Belting | Conveyor belts for various processes |

You can rely on these membranes to deliver performance, safety, and value—no matter your industry.

You unlock cleaner air and water when you choose advanced membranes. Their chemical resistance, thermal stability, and hydrophobicity help you meet strict regulations and boost efficiency. Industries worldwide trust these solutions for durability, low maintenance, and reliable performance. You lead your field by adopting innovative filtration for a safer, greener future.

FAQ

What makes PTFE Membrane ideal for industrial filtration?

You get unmatched chemical resistance and durability. PTFE Membrane stands strong in harsh environments. You achieve cleaner air and water with less maintenance.

Can you use PTFE Membrane for both air and liquid purification?

Yes! You can rely on PTFE Membrane for both air and liquid purification. You enjoy high efficiency and long-lasting performance in many industries.

How does PTFE Membrane help you meet environmental standards?

You meet strict regulations with PTFE Membrane. It removes fine particles and contaminants, helping you protect the environment and your business reputation.

Post time: Jul-30-2025