You want the best air quality for your environment. e-PTFE Membranes give you over 99.98% removal of 0.3 μm particles and nearly 100% for 2.5 μm particles. With ePTFE, you experience lower pressure loss, superior resistance to oily aerosols, and a remarkable reduction in indoor CO2 levels.

Key Takeaways

- e-PTFE membranes provide superior air filtration by capturing tiny particles efficiently while maintaining strong airflow and low resistance.

- These membranes resist harsh chemicals, extreme temperatures, and wear, making them durable and reliable in tough environments.

- Using e-PTFE membranes reduces maintenance needs and costs by lasting longer and requiring fewer filter replacements compared to traditional materials.

e-PTFE Membranes: What Makes Them Different

Unique Structure and Material Properties

You want a filter that stands out from the rest. e-PTFE Membranes offer a unique structure that delivers real results.

- Their raised fiber design uses both coarse and fine fibers, which control spacing and density for better filtration.

- Tiny crystalline nodes on and inside the fibers add strength and boost performance.

- The membrane’s smooth surface resists chemicals and keeps airflow high with low resistance.

- Unlike traditional filters, which let particles move deep into the fibers, e-PTFE Membranes trap particles right on the surface.

- You get a filter with smaller, uniform pores that keep your air cleaner.

You also benefit from advanced material properties. e-PTFE Membranes give you flexibility and precise control over pore size. Their hydrophobic nature keeps water out, even in humid conditions. The membrane’s chemical inertness means it stands up to acids and bases, so you can trust it in tough environments. You get abrasion resistance and UV stability, which means your filter lasts longer and works better outdoors.

Particle Capture and Filtration Mechanism

You want a filter that captures even the smallest particles. e-PTFE Membranes use an irregular fibrous structure, which holds onto particles more effectively than traditional filters.

- The membrane’s surface interacts with particles using forces like van der Waals and hydration forces.

- This means you get better capture, even for nanoparticles that might slip through other filters.

- The design keeps particles on the surface, so airflow stays strong and resistance stays low.

Chemical and Temperature Resistance

You need a filter that performs in any environment. e-PTFE Membranes resist harsh chemicals because of their strong molecular structure.

- The C-F bonds in the membrane protect it from acids, bases, and solvents.

- You can rely on these membranes in industrial settings where other filters might fail.

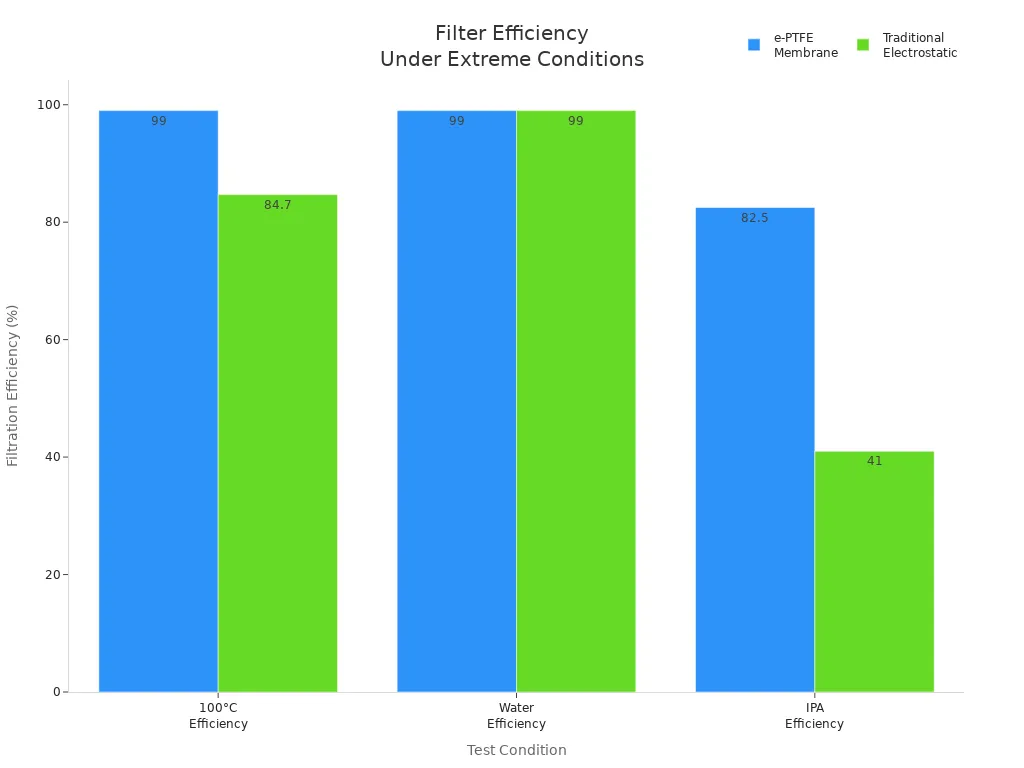

When it comes to temperature, e-PTFE Membranes keep working even in extreme heat or cold. The table below shows how they outperform traditional filters:

| Condition | e-PTFE Membrane Filter Performance | Traditional Electrostatic Filter Performance |

|---|---|---|

| At 100 °C (filtration efficiency) | Maintained >99% efficiency across all particle sizes | Dropped to 84.7% efficiency for 0.3–0.5 μm particles |

| After immersion in water | High efficiency with negligible decrease | High efficiency with negligible decrease |

| After immersion in IPA | Efficiency stabilized at 82.5% for 0.3–0.5 μm particles | Efficiency dropped sharply to 41% for 0.3–0.5 μm particles |

| Quality Factor (QF) at high temperature | Approximately 0.05 higher than electrostatic filters | Lower QF compared to e-PTFE filters |

| QF in water | About twice that of electrostatic filters (1.0–5.0 μm) | Lower QF |

| QF in IPA | Increased with particle size, higher than electrostatic filters | Lower QF |

You get peace of mind knowing your filter will not lose efficiency, even in the toughest conditions.

e-PTFE Membranes vs. Traditional Filter Materials: Performance Comparison

Filtration Efficiency and Air Quality

You want the cleanest air possible. e-PTFE Membranes deliver exceptional filtration efficiency, especially when you need to remove tiny particles like dust, bacteria, and even viruses. Studies show that PTFE filters outperform gelatin and polycarbonate filters for collecting submicrometer and nanoscale aerosols. You get the highest collection efficiency and the lowest pressure drop, which means you breathe cleaner air with less effort from your filtration system.

e-PTFE Membranes act as a chemical barrier, blocking particulates from entering the filter fabric. This keeps your air cleaner and extends the life of your filter. You also meet strict EPA requirements for particulate emissions, including PM2.5 standards, when you choose this advanced technology.

- You benefit from:

- Higher filtration efficiency for nanoparticles and bioaerosols

- Longer filter life due to reduced particulate penetration

- Improved indoor air quality metrics in controlled environments

Pressure Drop and Airflow

You want your air filtration system to work efficiently without wasting energy. Pressure drop is a key factor. Lower pressure drop means your system uses less energy to push air through the filter. e-PTFE Membranes offer a significantly lower initial pressure drop compared to traditional glass fiber filters. When combined with melt-blown nonwoven layers, these filters maintain high efficiency (about 99.984%) even after 120 days of use. You enjoy better airflow and longer filter life.

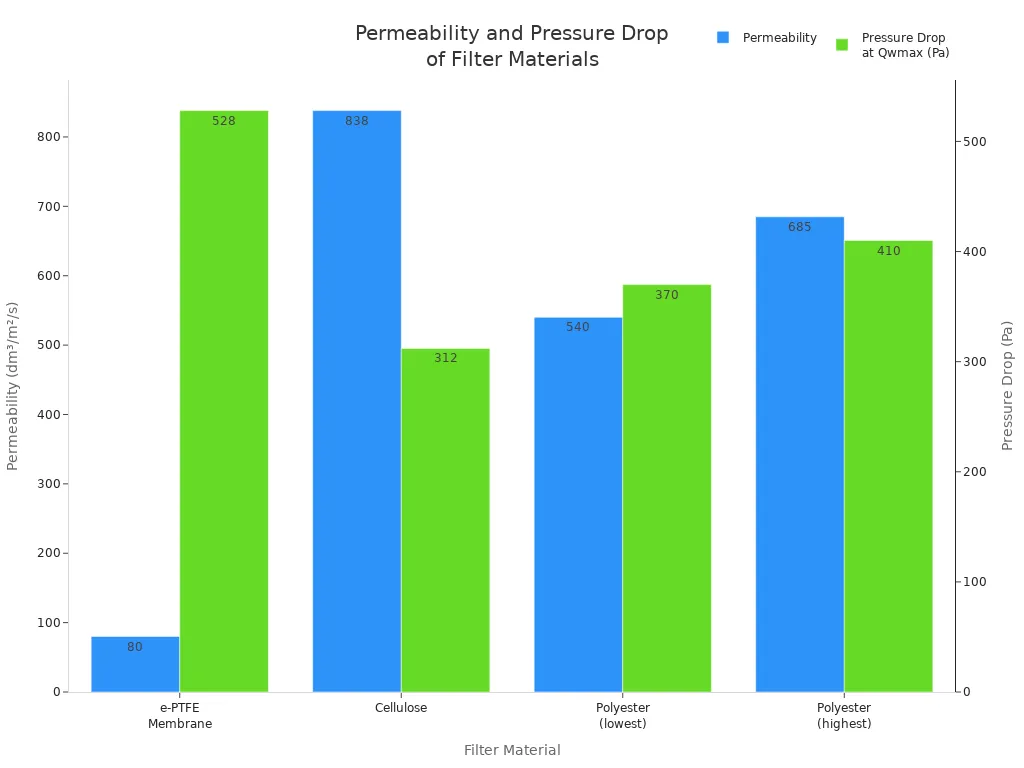

Here’s how pressure drop and permeability compare:

| Filter Type | Pressure Drop (Pa) | Permeability (dm³/m²/s) |

|---|---|---|

| e-PTFE Membrane | 528 | 80 |

| Cellulose (Traditional) | 312 | 838 |

| Polyester (Traditional) | 370-410 | 540-685 |

You see that e-PTFE Membranes provide higher filtration efficiency but may have a higher pressure drop at maximum airflow. However, the overall energy savings and improved air quality make them a smart choice for demanding environments.

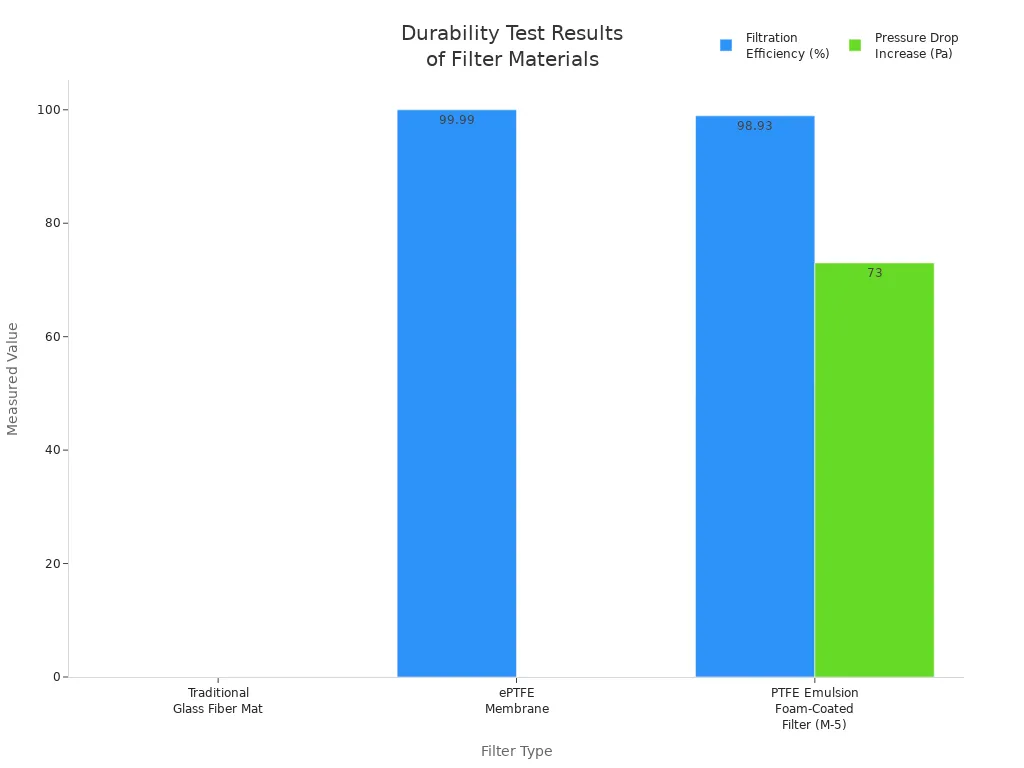

Durability and Lifespan

You want a filter that lasts. Traditional glass fiber mats often fail under continuous use, showing poor filtration and surface damage. e-PTFE Membranes achieve up to 99.99% filtration efficiency, but pure membranes can be fragile. When you use PTFE emulsion foam-coated filters, you get the best of both worlds: high abrasion resistance, stable pressure drop, and excellent self-cleaning. These filters maintain high efficiency (about 98.93%) even after 30 cycles of use.

| Filter Type | Filtration Efficiency (%) | Pressure Drop Increase (Pa) | Abrasion Resistance | Durability Characteristics |

|---|---|---|---|---|

| Traditional Glass Fiber Mat | Very poor | N/A | Significant loss | Low durability, fails standards |

| e-PTFE Membrane | Up to 99.99 | Low mechanical strength | Not specified | High filtration, limited durability |

| PTFE Emulsion Foam-Coated Filter | 98.93 after 30 cycles | Slow increase (319→392 Pa) | Lowest mass loss | High durability, long service life |

You get a filter that stands up to tough conditions and keeps working longer, reducing the need for frequent replacements.

Maintenance and Cleaning

You want to spend less time and money on filter maintenance. e-PTFE Membranes make this possible. Manufacturers report that pleated bag filters with e-PTFE Membranes last 2 to 3 times longer than traditional filters. In one case, a plant extended its filter change-out interval from every 5 weeks to every 24 months after switching to e-PTFE Membranes. You also save time during replacement, cutting labor hours from 12 to just 4.

With e-PTFE Membranes, you enjoy longer maintenance intervals, less downtime, and easier installation. Your operations run smoother, and you reduce maintenance costs.

Cost and Value

You want the best value for your investment. e-PTFE Membranes may cost more upfront, but you save money over time. Their high performance means you need less surface area, which reduces material costs. Techno-economic analysis shows that PTFE membranes lower total treatment costs and offer shorter pay-back periods. Their chemical resistance and durability mean fewer replacements and less maintenance, giving you a higher return on investment.

You benefit from:

- Lower long-term costs due to fewer replacements

- Superior durability in harsh environments

- Greater cost-effectiveness for both small and large-scale operations

When you choose e-PTFE Membranes, you invest in cleaner air, lower maintenance, and long-term savings.

Practical Applications and Suitability of e-PTFE Membranes

Ideal Use Cases for e-PTFE Membranes

You want a solution that stands up to the toughest demands. e-PTFE membranes shine in environments where high filtration efficiency, chemical resistance, and durability matter most. You see these membranes used in cleanrooms, semiconductor manufacturing, and pharmaceutical production. Their advanced structure blocks even the smallest particles, helping you meet strict air quality standards. You benefit from their ability to handle high temperatures and harsh chemicals, making them perfect for aerospace, automotive, and energy industries.

| Industry | Application Areas | Why Choose e-PTFE Membranes? |

|---|---|---|

| Aerospace | Sealing, filtration systems | Lightweight, durable, chemical resistant |

| Automotive | Fuel system, air filtration | Strong, reliable, withstands harsh fluids |

| Medical | Implants, drug delivery, filtration | Biocompatible, safe, long-lasting |

| Energy | Fuel cells, environmental filtration | High temp tolerance, sustainable |

Tip: You can rely on these membranes for critical operations where failure is not an option.

When Traditional Filter Materials Are Appropriate

You may find traditional filter materials more suitable in certain situations. If you need a cost-effective solution for general dust collection or air pollution control, fabric filters and nonwoven media work well. These materials offer easy processing and flexibility. In industries like power generation or steel manufacturing, traditional filters provide reliable performance and long service life. You also benefit from cleaning methods like pulse jet and reverse air, which extend filter life and reduce downtime.

- Fabric filters excel in industrial air filtration and flue gas control.

- Nonwoven media capture dust efficiently and last longer than woven fabrics.

- Custom fabric filters adapt to specific needs, improving compliance and efficiency.

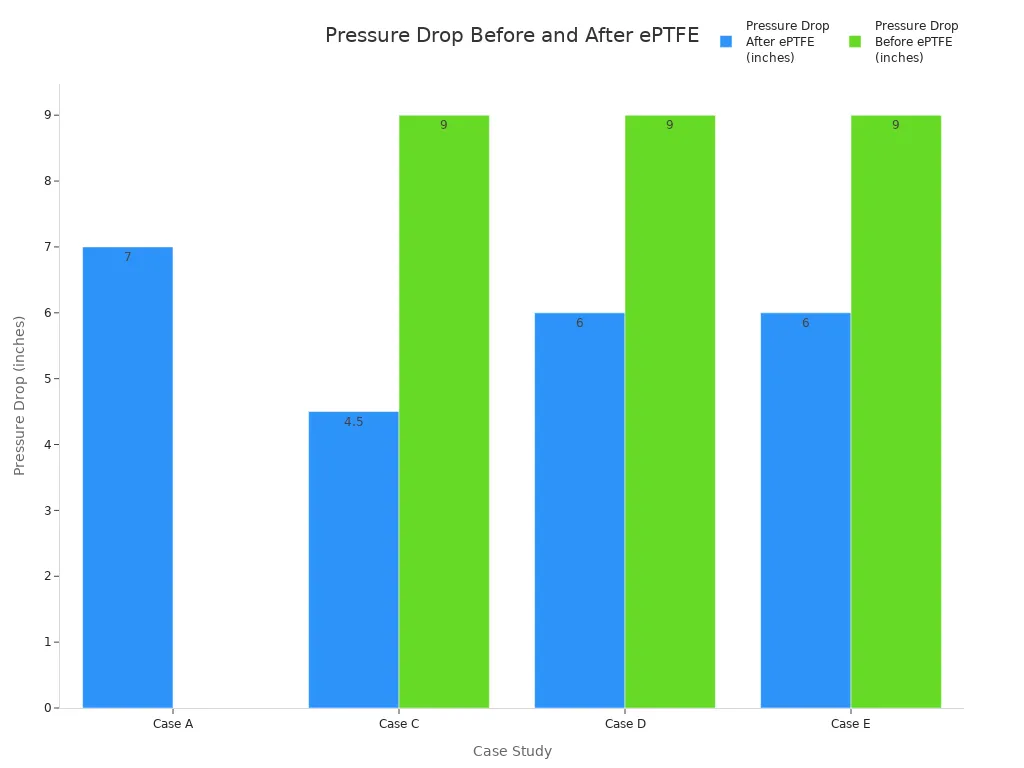

Industry Examples and Real-World Scenarios

You want proof that these solutions work. Many industries have switched to advanced membranes for better results. For example, a power plant replaced standard filters with e-PTFE membrane filters and saw pressure drop fall from 9 to 4.5 inches, cutting cleaning time in half. In another case, a steel mill upgraded its blower filtration and achieved 16 times longer filter life.

Traditional filters also deliver strong results. A textile plant in China switched to fine-fiber cellulose filters and saved over $1 million a year by reducing maintenance and extending service intervals. You can see that both options have their place, depending on your needs.

You gain unmatched efficiency and durability with e-PTFE Membranes, making them the top choice for demanding environments. Traditional filter materials still serve well for basic or budget-friendly needs. As industries push for cleaner air and smarter solutions, you see e-PTFE Membranes leading the way in advanced air filtration.

FAQ

What makes e-PTFE membranes better for air filtration?

You get higher efficiency, longer lifespan, and superior resistance to chemicals. Choose e-PTFE membranes for cleaner air and fewer filter changes.

Can you use e-PTFE membranes in humid or harsh environments?

You can trust e-PTFE membranes in humid, hot, or chemically aggressive settings. Their hydrophobic and chemical-resistant properties keep performance high.

Post time: Aug-09-2025