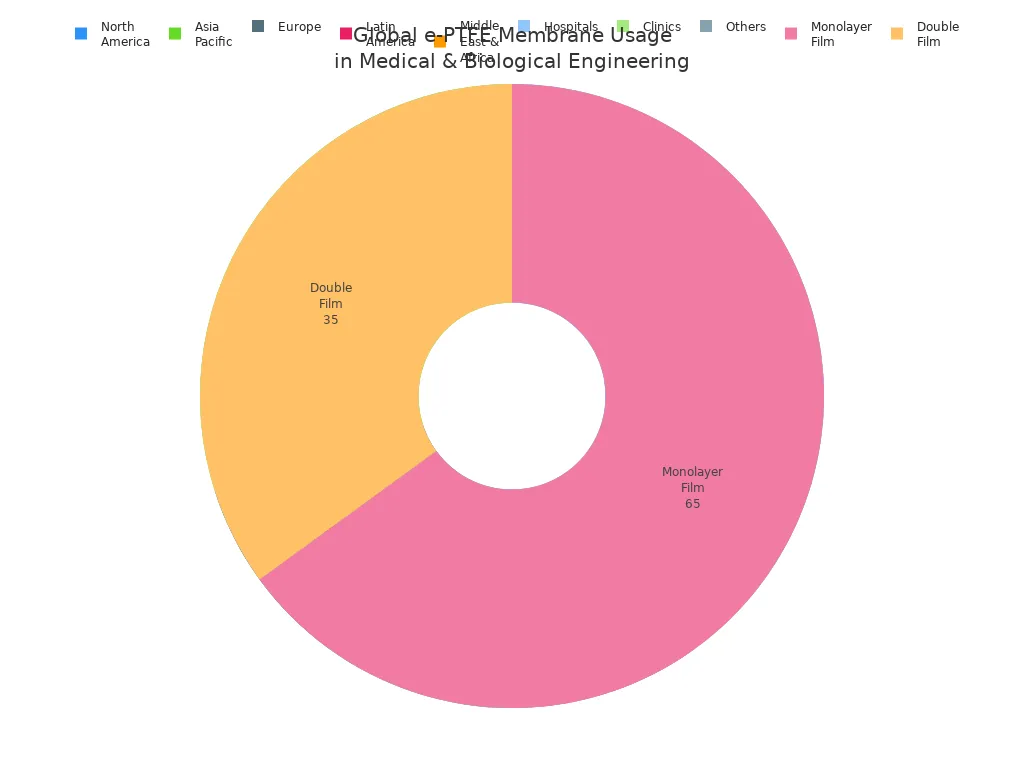

You see the impact of e-PTFE in medicine every day. Its unique structure supports better patient outcomes and enhances device performance. Hospitals and clinics worldwide choose e-PTFE for its biocompatibility and strength. The global market continues to grow, as shown below:

| Metric/Aspect | Value/Detail |

|---|---|

| Market Size (2025) | USD 1.09 billion |

| Projected Market Size (2030) | USD 1.47 billion |

| CAGR (Forecast Period) | 6.1% |

| Key Medical Uses | Implants, prosthetics due to chemical inertness, low friction, high temperature resistance |

You may also find ePTFE Membrane For Textile solutions in advanced medical and biological engineering.

Key Takeaways

- e-PTFE membranes offer excellent biocompatibility, chemical resistance, and mechanical strength, making them safe and durable for medical devices and implants.

- Their controlled porosity allows precise filtering and supports tissue regeneration, improving healing and reducing infection risks.

- e-PTFE membranes are widely used in implants, grafts, wound healing, and filtration, helping healthcare providers deliver better patient outcomes with innovative and reliable solutions.

Unique Properties of e-PTFE Membranes

Biocompatibility and Safety

You want every medical device to be safe and gentle for the human body. e-PTFE membranes help you achieve this goal. Clinical studies show that e-PTFE works well in many medical devices, such as stents, grafts, and heart repair patches. Doctors and scientists trust e-PTFE because it does not react with body tissues. Patients experience fewer complications, and the healing process often improves. You can rely on e-PTFE to deliver high success rates in surgeries and implants. Its biocompatibility gives you confidence in every application.

When you choose e-PTFE, you choose a material that supports healing and protects patients.

Chemical and Thermal Resistance

You need materials that stand up to harsh chemicals and high temperatures in medical settings. e-PTFE gives you this strength. It resists acids, solvents, and cleaning agents, so you can use it in tough environments. Unlike polyester, e-PTFE does not trigger strong tissue reactions or lose its shape. It stays stable and safe, even after repeated sterilization cycles.

Here is a quick comparison:

| Property/Aspect | ePTFE (Expanded PTFE) | Polyester (Common Medical Polymer) |

|---|---|---|

| Chemical Resistance | Very high; chemically inert PTFE surface | Lower chemical resistance |

| Tissue Reaction | Low-grade tissue reaction; less inflammatory | More readily induces inflammatory reaction |

| Dimensional Stability | Better stability; less dilation | Tends to dilate more |

| Thrombogenicity | Less thrombogenic surface | More thrombogenic |

| Additional Properties | Porous, flexible, biocompatible, hydrophobic | N/A |

You can trust e-PTFE to maintain its integrity during autoclaving and other sterilization processes. This reliability means your devices stay safe and effective for longer.

- e-PTFE membranes resist a wide range of chemicals, including acids and solvents.

- They remain stable under high heat, making them ideal for repeated sterilization.

- Their flexibility and durability support long-term use in demanding medical environments.

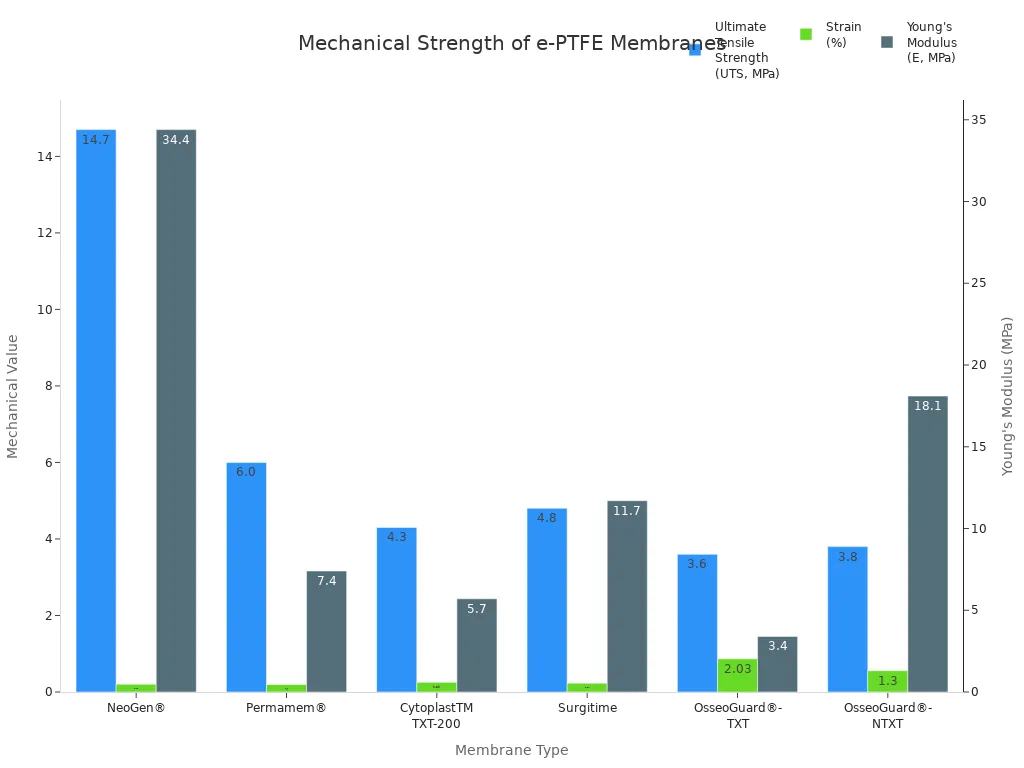

Mechanical Strength and Durability

You want your medical devices to last and perform under pressure. e-PTFE membranes deliver impressive mechanical strength and flexibility. Laboratory tests show that e-PTFE membranes, like NeoGen®, reach ultimate tensile strengths up to 14.7 MPa. This strength helps your devices resist tearing and maintain their shape during use.

You also benefit from the durability of e-PTFE. It stands up to hydrolysis, weathering, and high pressure. Compared to polyurethane, e-PTFE offers much better resistance to wear and tear. This means your devices last longer and require less maintenance.

- e-PTFE membranes combine strength and flexibility, preventing cracks and tears.

- Their durability supports reliable, long-term performance in medical devices.

Controlled Porosity and Permeability

You need membranes that let the right things pass through while blocking unwanted particles. e-PTFE gives you control over pore size and permeability. Manufacturers can adjust the pore size from nanometers to micrometers, depending on your needs. This flexibility allows you to use e-PTFE in applications like sterile filtration, tissue engineering, and wound healing.

| Property | Details |

|---|---|

| Pore Size Range | From nanometers to micrometers |

| Typical Pore Sizes | 0.1 to 5 microns (e.g., syringe filters) |

| Application | Sterile filtration of liquids, biological samples |

| Function | High microbial retention, contaminant prevention |

The level of porosity in e-PTFE membranes shapes their performance in tissue engineering. High-porosity membranes allow nutrients and fluids to pass, supporting bone and tissue growth. Low-porosity membranes block bacteria and unwanted cells, reducing infection risk. You can choose the right membrane for your specific application, balancing protection and regeneration.

With e-PTFE, you unlock the power to design solutions that fit your exact needs in medicine and biology.

e-PTFE Applications and Advantages in Medicine and Biology

Medical Implants and Grafts

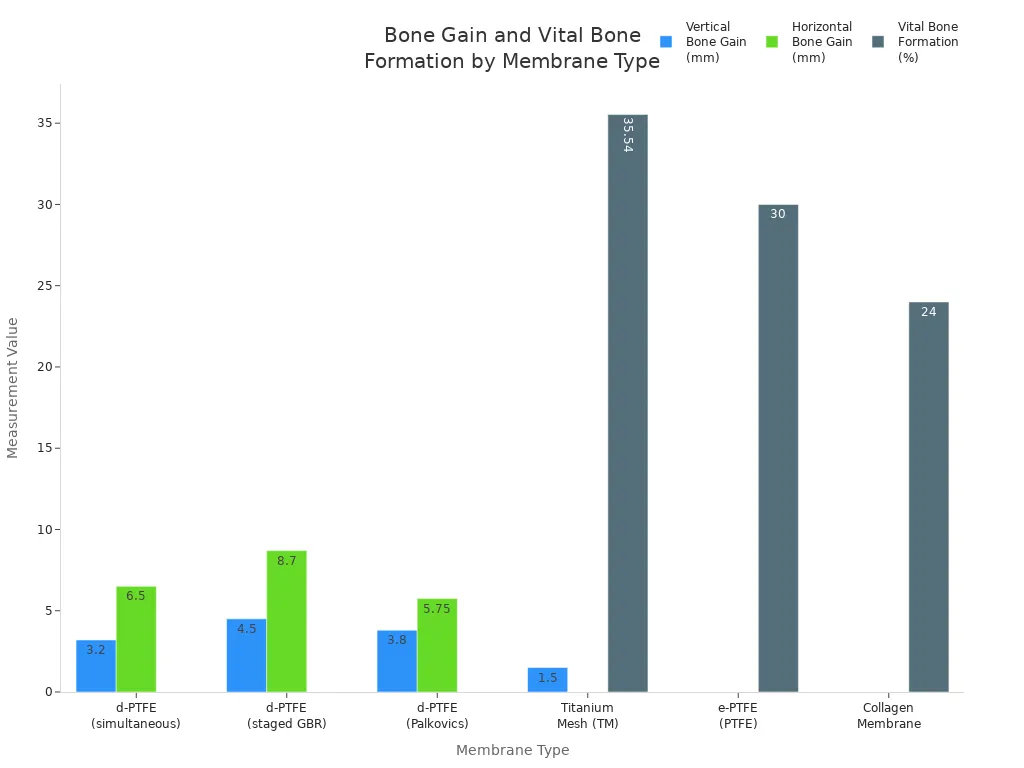

You can transform patient outcomes with advanced medical implants and grafts. e-PTFE membranes play a vital role in procedures like guided bone regeneration (GBR) and vertical alveolar ridge augmentation. Surgeons often combine these membranes with titanium meshes or reinforce them with titanium for extra support. This approach creates a protected space for bone to grow, leading to successful bone regeneration and improved stability for dental implants.

| Aspect | Details |

|---|---|

| Common Medical Implants/Grafts Using e-PTFE Membranes | Titanium meshes and titanium-reinforced PTFE membranes used primarily in guided bone regeneration (GBR) and vertical alveolar ridge augmentation, often combined with autogenous bone grafts. |

| Clinical Outcomes | Successful bone regeneration by creating a secluded space for bone growth. Generally positive outcomes reported in GBR and alveolar ridge reconstruction. |

| Most Common Complication | Membrane exposure (classified into four classes: small exposure without infection, large exposure without infection, exposure with purulent exudate, abscess without exposure). Exposure can negatively affect outcomes. |

| Comparative Findings | Newer dense PTFE (d-PTFE) membranes with smaller pore sizes show less negative impact on clinical results compared to e-PTFE membranes, possibly due to better barrier properties against bacteria. Some studies report no significant difference in clinical performance between e-PTFE and d-PTFE membranes. |

| Management Strategies | Classifications of membrane exposure guide treatment; some exposures managed by removal of exposed portion while maintaining membrane in place, with regular irrigation and monitoring. |

You see positive clinical results with e-PTFE membranes, especially in bone regeneration and ridge reconstruction. Even when complications like membrane exposure occur, you can manage them with careful monitoring and targeted interventions. The ability to customize pore size and reinforce membranes with titanium gives you flexibility to meet each patient’s needs.

In vascular grafts, e-PTFE stands out for its porous structure. This design influences how the body responds to the implant. The membrane’s porosity helps modulate the immune response and supports long-term stability. Compared to other materials, e-PTFE offers superior mechanical strength and hemocompatibility, making it a trusted choice for vascular surgeons.

Tissue Regeneration and Wound Healing

You can inspire healing and restore hope with e-PTFE membranes in tissue regeneration and wound care. Researchers have shown that these membranes promote bone healing in critical-size defects. In animal studies, e-PTFE membranes led to complete bone healing, while control groups showed only partial recovery. When combined with growth factors like rhBMP-2, the results become even more impressive, with faster and more robust bone formation.

| Study (Author, Year) | Animal Model | Membrane Type | Defect Model | Evaluation Time & Method | Key Findings |

|---|---|---|---|---|---|

| Dahlin 1994 | Rat mandible | e-PTFE | Critical size through-and-through defects | 6 weeks, histology | Complete bone healing with membrane; control defects showed incomplete healing with connective tissue presence |

| Schenk 1994 | Dog mandible | Standard & reinforced e-PTFE | Critical size defects | 2 & 4 months, histology | Membrane sites showed significantly better bone healing than controls; bone regeneration followed normal developmental sequence |

| Linde 1995 | Rat mandible | e-PTFE + rhBMP-2 | Critical size defects | 12 & 24 days, histomorphological scoring | Combination of e-PTFE membrane with rhBMP-2 yielded superior bone healing and maintained bone contour compared to membrane alone |

| Zellin 1995 | Rat mandible | Various membranes including e-PTFE | Bilateral critical size defects | 6 weeks, SEM & histology | e-PTFE showed good osteopromotive effect and low inflammatory response compared to other membranes |

You can also rely on e-PTFE for chronic wound management. In preclinical studies, modified e-PTFE membranes accelerated healing in diabetic wounds and reduced inflammation. These membranes act as advanced wound dressings, protecting the wound, minimizing immune response, and supporting faster recovery. You give patients a better chance at healing, even in challenging cases.

When you choose e-PTFE membranes for tissue regeneration and wound healing, you empower the body’s natural ability to repair and renew.

Filtration and Barrier Membranes

You protect patients and healthcare workers every day with effective filtration and barrier solutions. e-PTFE membranes set the standard in medical filtration, thanks to their precisely controlled pore sizes and hydrophobic nature. These membranes trap sub-micron particles, including bacteria and viruses, while allowing air and moisture vapor to pass through.

- e-PTFE membranes filter out particles as small as 0.3 microns, making them ideal for surgical masks, sterile venting, and IV infusion sets.

- Their hydrophobic surface prevents liquid penetration, reducing the risk of contamination and infection.

- You find e-PTFE membranes in HEPA and ULPA filters, where they ensure ultra-clean air in hospitals and laboratories.

You can trust these membranes to maintain high filtration efficiency, even in moist environments. Their durability and biocompatibility make them a reliable choice for critical medical and biological barrier applications.

Comparison with Alternative Materials

You want the best for your patients, so you compare materials carefully. e-PTFE membranes offer a unique combination of strength, flexibility, chemical inertness, and porosity. These properties allow tissue to grow into the membrane, supporting integration in vascular grafts and hernia repairs. Silicone provides excellent flexibility and oxygen permeability, while polyurethane offers tunable mechanical properties. However, polyurethane may degrade over time, and polyethylene, though cost-effective, lacks the same flexibility and lubricity.

| Property | e-PTFE Membranes | Silicone | Polyurethane | Polyethylene |

|---|---|---|---|---|

| Flexibility | Moderate; soft and flexible | High; very flexible | Tunable; from soft to rigid | Varies; LDPE flexible, HDPE rigid |

| Chemical Resistance | High; excellent chemical inertness | Good; less resistant than PTFE in extreme environments | Moderate; may degrade without coatings | Good; resistant to many chemicals |

| Biocompatibility | Good; supports tissue ingrowth | Excellent; widely used in implants | Good; used in vascular grafts and heart valves | Good; generally biocompatible |

| Surface Lubricity | High; low friction | Low | Low to moderate | Low |

| Oxygen Permeability | Low | High; beneficial for wound healing | Varies | Low |

| Cost | High | Moderate | Moderate | Low |

You see that e-PTFE and d-PTFE membranes provide bone regeneration outcomes that match or surpass those of collagen membranes and titanium meshes. Non-resorbable membranes like e-PTFE require a second surgery for removal, while resorbable options avoid this step but may degrade unpredictably. Titanium reinforcement increases stiffness but can complicate removal. You balance these factors to choose the right solution for each patient.

Regulatory, Sustainability, and Innovation

You navigate a complex regulatory landscape to bring safe and effective products to market. e-PTFE membranes have received FDA and EMA approvals for use in medical devices, including vascular grafts and drug delivery systems. Manufacturers invest in quality control and compliance to meet these high standards. Regulatory requirements drive innovation and ensure that you deliver the best possible care.

| Year | Company | Regulatory Approval | Device/Application | Notes on Regulatory Environment |

|---|---|---|---|---|

| 2021 | Nitto | FDA approval | Novel ePTFE membrane for drug delivery system | Highlights stringent regulatory requirements with high costs and lengthy processes |

| 2023 | Paradyne Medical | FDA approval | New ePTFE-based vascular graft | Emphasizes impact of compliance costs and timelines on market entry |

| N/A | N/A | General regulatory environment (FDA US, EMA Europe) | Medical ePTFE membranes broadly | Regulatory challenges include stringent requirements, quality control, and compliance costs impacting growth and market dominance in North America and Europe |

You also care about sustainability. Many e-PTFE membrane products now comply with ISO 14001 environmental management standards. Companies are eliminating harmful chemicals and exploring greener production methods. Recycling initiatives and research into bio-based alternatives help reduce environmental impact. You support a future where medical innovation and environmental responsibility go hand in hand.

Recent innovations inspire you to push boundaries. Advanced processing techniques allow you to customize e-PTFE membranes for each patient, creating ultra-thin, strong, and flexible implants. Manufacturers now offer rapid prototyping and scalable production, ensuring you get high-performance components tailored for cardiovascular and general surgery. These breakthroughs help you deliver better outcomes and brighter futures for your patients.

- You unlock new possibilities in medicine with e-PTFE membranes.

- Their unique microporous structure and biocompatibility support safer surgeries and faster healing.

- You see ongoing innovation, from antimicrobial coatings to smart implants, driving better patient care and expanding future healthcare solutions.

FAQ

What makes e-PTFE membranes special in medical applications?

You benefit from e-PTFE’s unique structure. It offers biocompatibility, strength, and controlled porosity. These features help you achieve safer surgeries and faster healing.

Can you use e-PTFE membranes for filtration in hospitals?

Absolutely! You can rely on e-PTFE membranes to filter bacteria and viruses. They keep air and fluids clean, protecting both patients and healthcare workers.

Are e-PTFE membranes safe for long-term use in the body?

Yes! You can trust e-PTFE membranes. They resist reactions with body tissues and maintain their properties over time, supporting long-term patient health.

Post time: Aug-13-2025