When I evaluate materials for water filtration, Teflon Material stands out for its unmatched combination of properties. Its chemical resistance ensures that contaminants don’t compromise the filtration process. The non-stick surface enhances efficiency by preventing clogging, while its durability allows it to withstand extreme temperatures and pressures. These qualities make it a preferred choice in industries adopting advanced technologies. For example, the growing demand for ePTFE Air Filter Membrane in filtration systems highlights how Teflon Material meets the challenges of modern water purification needs. Moreover, its ability to support sustainable practices by reducing waste and energy consumption strengthens its position as an environmentally conscious solution.

Key Takeaways

- Teflon resists chemicals, keeping water clean and safe to use.

- Its smooth surface stops clogs, making filtration work better and cheaper.

- Teflon stays strong in tough conditions, so it’s great for home and factory filters.

Properties of Teflon Material for Water Filtration

Chemical Resistance and Contamination Prevention

When I consider materials for water filtration, chemical resistance is a critical factor. Teflon Material excels in this area, offering unparalleled protection against corrosive substances. Its high fluorine content creates a robust shield around carbon atoms, preventing chemical interactions that could compromise the material’s integrity. This makes it ideal for applications where exposure to aggressive chemicals is unavoidable.

Teflon (PTFE) is recommended for highly corrosive applications due to its ability to withstand chemical attacks and maintain its integrity over time. The material’s high fluorine content allows it to effectively shield carbon atoms from chemical interactions, ensuring longevity in corrosive environments.

In laboratory tests, Teflon Material has demonstrated its resilience under extreme conditions. For instance:

- Teflon PFA sensors remain intact even when exposed to harsh chemicals.

- Its non-reactive nature prevents harmful substances from leaching, ensuring purity in sensitive applications.

- It can withstand a wide range of corrosive substances, making it indispensable in chemical processing and laboratory equipment.

This exceptional chemical resistance not only ensures the longevity of filtration systems but also prevents contamination, safeguarding water quality.

Non-Stick Surface for Enhanced Filtration Efficiency

The non-stick surface of Teflon Material is another feature that sets it apart. This property minimizes the adhesion of particles, reducing the risk of clogging in filtration systems. As a result, water flows more freely, enhancing the overall efficiency of the filtration process. I’ve observed how this feature significantly reduces maintenance requirements, saving both time and resources.

In practical applications, the non-stick nature of Teflon Material ensures that even in high-particulate environments, the filtration system operates smoothly. This makes it a preferred choice for industries where uninterrupted performance is crucial.

Durability Under High Temperatures and Pressures

Durability is a hallmark of Teflon Material, especially under extreme conditions. Its ability to withstand high temperatures and pressures makes it a reliable choice for demanding water filtration applications. Quantitative data from wear tests highlight its low coefficient of friction, approximately 0.18, which contributes to its longevity. Adhesion tests further demonstrate its robustness, with a critical load for adhesion failure at around 8.5 N.

This durability ensures that Teflon Material maintains its performance over time, even in the most challenging environments. Whether it’s industrial water treatment or specialized laboratory settings, its resilience under stress makes it an invaluable asset.

Environmental Advantages of Teflon Material

Longevity Reducing Waste in Filtration Systems

When I evaluate the environmental impact of filtration systems, longevity plays a crucial role. Teflon Material stands out due to its exceptional durability, which significantly reduces waste. Its robust structure ensures that filtration components last longer, minimizing the need for frequent replacements. This durability translates into fewer discarded materials, contributing to a cleaner environment.

In my experience, industries that adopt Teflon-based filtration systems benefit from reduced operational costs and waste management challenges. The material’s ability to withstand wear and tear ensures that systems remain functional for extended periods, making it a sustainable choice for water purification.

Energy Efficiency in Water Filtration Processes

Energy efficiency is another area where Teflon Material excels. Its unique properties, such as the hydrophobic surface and smooth nanochannels, enhance water transport efficiency. This reduces the energy required for filtration processes, making it an eco-friendly option.

‘Fluorine is negatively charged so there’s a very strong electrostatic repulsion with chloride ions, so nothing passes through. This is a very efficient method of water desalination.’

I’ve observed how the hydrophobic nature of Teflon-inspired surfaces suppresses water cluster formation, allowing faster diffusion of water molecules. This feature not only improves filtration speed but also lowers energy consumption.

- The interior surface of the nanochannels is coated with fluorine atoms, enhancing water transport efficiency.

- The hydrophobic nature of Teflon-inspired surfaces suppresses water cluster formation, allowing faster diffusion of water molecules.

- These materials have the potential to outperform existing purification technologies, indicating significant environmental benefits.

By optimizing energy use, Teflon Material supports industries in achieving their sustainability goals while maintaining high filtration performance.

Contribution to Sustainable Water Purification Practices

Sustainability is at the heart of modern water purification practices, and Teflon Material contributes significantly to this effort. Its ability to prevent contamination, reduce waste, and lower energy consumption aligns with global environmental objectives.

In wastewater treatment and seawater desalination, Teflon-based membranes have demonstrated remarkable efficiency. Their non-reactive nature ensures that harmful substances don’t leach into the environment, safeguarding ecosystems. Additionally, the material’s longevity reduces the strain on resources, promoting a circular economy.

I’ve seen firsthand how Teflon Material enables industries to adopt greener practices without compromising on performance. Its versatility ensures that it remains a valuable asset in the quest for sustainable water management.

Applications of Teflon Material in Water Filtration

Industrial Water Treatment and Wastewater Management

In industrial water treatment, Teflon Material plays a pivotal role. Its chemical resistance ensures that filtration systems can handle aggressive substances without degradation. I’ve seen how industries benefit from its durability, especially in wastewater management, where exposure to harsh chemicals is common. The material’s ability to withstand high temperatures and pressures makes it indispensable for processes like desalination and chemical filtration.

Teflon-based membranes have demonstrated exceptional performance in reducing operational downtime. Their longevity minimizes the need for frequent replacements, which translates into cost savings and improved efficiency.

Industries such as chemical processing and pharmaceuticals rely heavily on Teflon filters. These filters not only enhance operational efficiency but also comply with stringent environmental regulations, making them a sustainable choice for large-scale water treatment.

Residential and Commercial Filtration Systems

Teflon Material has also revolutionized residential and commercial water filtration systems. Its non-stick surface prevents clogging, ensuring consistent water flow and reducing maintenance requirements. I’ve observed how its superior filtration efficiency and long lifespan make it a preferred choice for homeowners and businesses alike.

- The global PTFE membrane market, valued at approximately USD 2,753.7 billion in 2023, is projected to grow at a CAGR of 5.9% from 2024 to 2030.

- This growth reflects the increasing demand for high-performance filtration solutions in residential and commercial settings.

The material’s ability to maintain water purity while reducing energy consumption aligns with the needs of modern filtration systems. Its adoption continues to rise as consumers prioritize efficiency and sustainability.

Specialized Uses in Medical and Laboratory Settings

In medical and laboratory environments, precision and reliability are non-negotiable. Teflon Material excels in these settings due to its non-reactive nature and exceptional filtration capabilities. I’ve seen how it ensures the purity of liquids and gases, which is critical for sensitive applications like pharmaceutical production and scientific research.

PTFE membranes are widely used in sterile filtration processes, where contamination prevention is paramount. Their chemical resistance and thermal stability make them ideal for handling aggressive solvents and high-temperature sterilization.

From filtering biological samples to purifying medical-grade water, Teflon-based solutions support advancements in healthcare and research. Their versatility and performance make them an invaluable asset in these specialized fields.

Teflon Material offers unmatched reliability and efficiency in water filtration. Its ability to capture particles as small as 1.0 μm ensures superior filtration performance:

- PM10 filtration efficiency: 0.87% to 24.93%

- PM2.5 filtration efficiency: 1.21% to 18.69%

- PM1.0 filtration efficiency: 0.56% to 16.03%

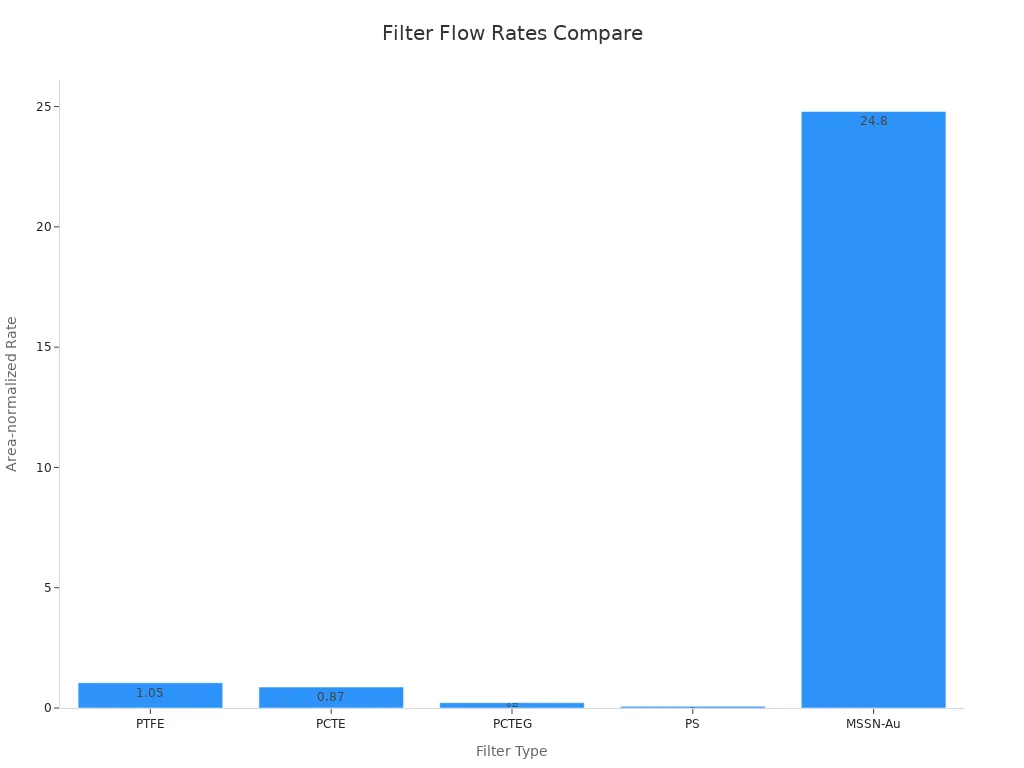

Compared to traditional filters, Teflon Material demonstrates faster water flux and higher flow rates, as shown below:

| Filter | 1 L Water Flux Time @ 97.9 kPa (min) | Absolute Water Flow Rate (mL • min−1) | Area-normalized Water Flow Rate (mL • min−1 • mm−2) |

|---|---|---|---|

| PTFE | 7.79 ± 0.07 | 128 ± 1.14 | 1.05 |

| PCTE | 9.37 ± 0.21 | 107 ± 2.37 | 0.87 |

| PCTEG | 37.8 ± 1.17 | 26.4 ± 0.82 | 0.22 |

| PS | 148 ± 3.53 | 6.76 ± 0.16 | 0.07 |

| MSSN-Au | 6.39 ± 0.17 | 156 ± 4.11 | 24.8 |

This versatility ensures its relevance across industries, from wastewater treatment to medical applications. By reducing waste and energy consumption, Teflon Material supports sustainable water management, contributing to a healthier environment.

FAQ

What makes Teflon Material superior to traditional filtration materials?

Teflon Material offers unmatched chemical resistance, durability, and non-stick properties. These features ensure efficient filtration, reduced maintenance, and longer system lifespan compared to traditional materials.

Can Teflon-based membranes handle extreme conditions?

Yes, Teflon-based membranes perform exceptionally under high temperatures and pressures. Their robust structure ensures reliability in demanding industrial and specialized applications.

How does Teflon Material contribute to sustainability?

Teflon Material reduces waste through its longevity and minimizes energy consumption during filtration. Its eco-friendly properties align with sustainable water management practices.

Post time: Jun-03-2025