You rely on a Ptfe Membrane when you need reliable filtration. This semi-porous material lets gases or liquids pass but stops particles and bacteria. Many industries choose ePTFE Membrane For Textile for its advanced performance. The global market for PTFE membranes continues to grow, as shown below:

| Metric | Value (USD Billion) | Period |

|---|---|---|

| Market Size (2025) | 0.98 | 2025 |

| Market Size (2034) | 1.40 | 2034 |

| Compound Annual Growth Rate | 4.0% | 2025-2034 |

| North America Market Size (2034) | 0.48 | 2034 |

| Asia-Pacific Market Size (2034) | 0.30 | 2034 |

Key Takeaways

- PTFE membranes have tiny pores that filter out particles and bacteria with over 99.99% efficiency, making them ideal for clean and sterile environments.

- These membranes repel water and oil, resist harsh chemicals, and last longer than traditional filters, saving you time and money on maintenance.

- You can use PTFE membranes in many industries like healthcare, automotive, and water treatment, and proper cleaning and inspection keep them working well for years.

How PTFE Membrane Works

Microporous Structure and Filtration Mechanism

You can rely on the unique microporous structure of a Ptfe Membrane to achieve high filtration efficiency. The membrane contains countless tiny pores, which you can control during manufacturing to match specific filtration needs. These pores range from 0.22 µm to 50 µm, allowing you to filter out particles, bacteria, and even some viruses. When you use a membrane with a pore size of 0.22 µm, you remove extremely fine particles and meet sterilization standards with over 99.99% efficiency.

Here is a quick overview of typical PTFE membrane properties:

| Parameter | Details |

|---|---|

| Typical Pore Size Range | 0.22 µm to 50 µm |

| Filtration Efficiency | >99.99% for pore sizes as low as 0.1 µm |

| Airflow Rate | 0.25 – 70 l/h/cm² |

| Water Entry Pressure | 10 – 800 mbar |

| Membrane Thickness | 0.1 – 3.0 mm |

| Filter Type | Depth filter |

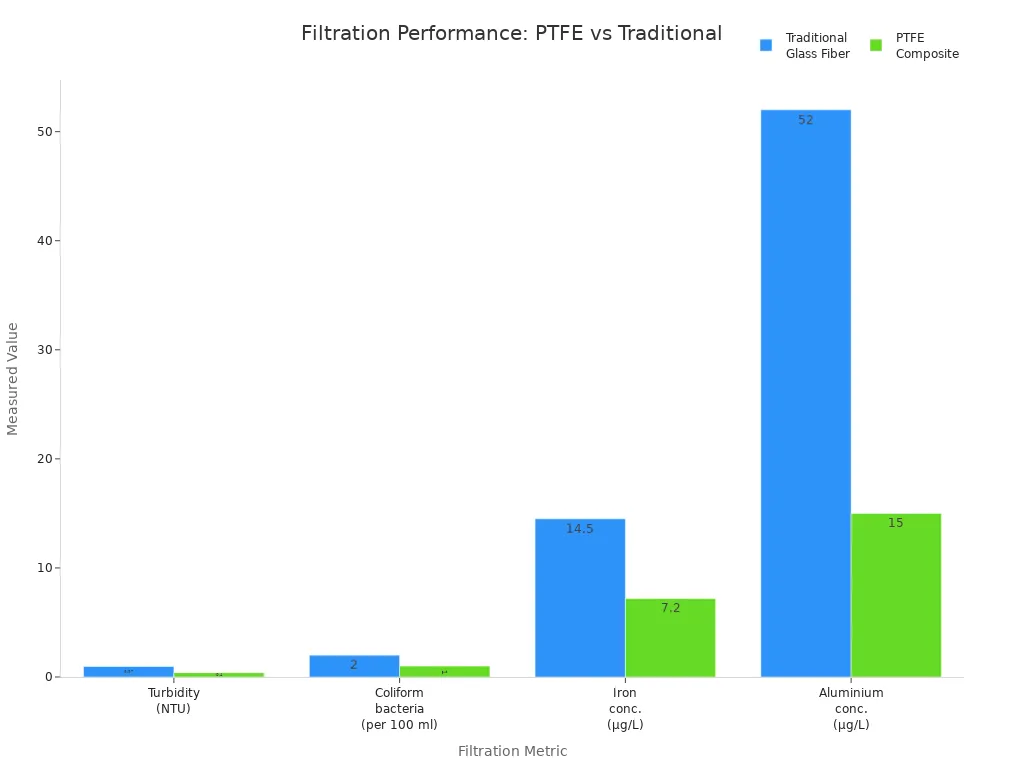

You benefit from the surface loading mechanism of Ptfe Membrane, which traps particles on the surface rather than deep inside. This design gives you lower initial pressure drop and higher durability compared to traditional glass fiber filters. If you combine PTFE membranes with melt-blown nonwoven layers, you can triple the dust holding capacity and maintain high filtration efficiency for months. The thin nanofibrous structure also provides excellent mechanical strength, so you get both durability and high performance.

- Common PTFE membrane pore sizes include 0.22 µm, 0.45 µm, 0.8 µm, and 1.0 µm.

- Smaller pore sizes are ideal for high-purity applications such as ultrapure water and pharmaceutical-grade filtration.

- The uniform microporous structure allows precise control over filtration performance.

Tip: When you select a PTFE membrane, always check the pore size and thickness to match your filtration needs.

Hydrophobic and Oleophobic Properties

You experience the benefits of hydrophobic and oleophobic properties every time you use a Ptfe Membrane in wet or oily environments. The membrane repels water and oil, thanks to its low surface energy and special surface structure. Water contact angles for PTFE membranes often reach 140° or higher, which means water beads up and rolls off instead of soaking through. Nanofibrous PTFE membranes with microparticles can even achieve superhydrophobicity, with contact angles exceeding 150°.

- Flat sheet PTFE membranes have contact angles around 140°.

- Nanofibrous PTFE membranes show contact angles around 144°.

- PTFE membranes maintain high hydrophobicity even after exposure to oily brine or harsh chemicals.

- PVDF membranes, by comparison, are hydrophilic and have much lower contact angles.

You can trust PTFE membranes to resist wetting and fouling, even in challenging conditions. Scientific studies show that dip-coated FOTS-PTFE membranes keep their non-wetting properties after exposure to acids, bases, and UV light. The combination of hierarchical surface structures and low surface energy gives you stable performance and durability.

Note: Hydrophobicity is critical for applications like membrane distillation, waterproof textiles, and outdoor gear.

Selective Permeability and Chemical Resistance

You gain a major advantage with the selective permeability of Ptfe Membrane. The membrane allows gases to pass freely while blocking liquids, thanks to its hydrophobic nature and controlled pore size. This property is essential for gas filtration, as it prevents water vapor from condensing and blocking the pores. In liquid filtration, the membrane resists fouling by repelling water and biological contaminants, which helps you maintain flow rates and reduce cleaning frequency.

PTFE membranes also offer outstanding chemical resistance. You can use them with strong acids, solvents, and salts at various concentrations and temperatures. For example, PTFE resists sulphuric acid up to 95% concentration at temperatures from 20°C to 100°C. It also withstands exposure to acetic acid, acetone, benzene, caustic soda, and many other chemicals.

| Chemical | Concentration | Temperature | Resistance |

|---|---|---|---|

| Sulphuric Acid | Up to 95% | 20-100°C | Resistant |

| Acetic Acid | 10%/Glacial | 20-100°C | Resistant |

| Acetone | Pure | 20-100°C | Resistant |

| Benzene | Pure | 20-100°C | Resistant |

| Caustic Soda | Any | 20-100°C | Resistant |

| Chromic Acid | 80% | 20-100°C | Resistant |

You can rely on PTFE membranes for consistent performance in harsh chemical and thermal environments. The non-stick surface also helps minimize particle adhesion and fouling, which extends the operational lifespan of your filtration system.

Tip: For applications involving aggressive chemicals or extreme temperatures, PTFE membranes provide reliable protection and long-term durability.

PTFE Membrane: Properties, Benefits, and Applications

Key Advantages for Filtration and Protection

You gain many benefits when you choose a Ptfe Membrane for filtration and protection. The membrane stands out for its durability and efficiency. You notice that it lasts about twice as long as standard filter bags. You spend less time and money on maintenance because the membrane resists wear and tear. The slick surface makes cleaning easier, so you avoid frequent shutdowns and keep your system running smoothly.

- You experience up to eight times higher filtration efficiency compared to traditional filter bags.

- The membrane maintains steady airflow due to its small pore size.

- You save energy because the membrane requires less compressed air and has lower resistance at startup.

- The hydrophobic surface prevents moisture-related fouling, which keeps filtration performance high even in sticky or wet conditions.

You also benefit from the membrane’s chemical inertness and mechanical stability. Unlike cellulose or nylon membranes, Ptfe Membrane resists chemical and biological fouling. It stays strong under high pressure and temperature, which means you can rely on it in harsh environments. The membrane’s long lifespan and reduced maintenance needs offset its higher initial cost, making it a smart investment for long-term use.

Tip: You can improve operational efficiency and reduce energy costs by switching to PTFE membranes in your filtration systems.

Common Uses in Industry, Medical, and Consumer Products

You find Ptfe Membrane used in many industries because of its unique properties. The membrane’s high chemical resistance, temperature stability, and breathability make it valuable in demanding applications. Here is a table showing where you see PTFE membranes and why they are chosen:

| Industrial Sector | Main Reason for Use |

|---|---|

| Electronics | Protects sensitive components from moisture and dust; supports miniaturized devices. |

| Automotive | Increases durability, reduces emissions, improves fuel efficiency; used in fuel systems and seals. |

| Aerospace | Lightweight and strong; improves safety and fuel efficiency in aircraft parts. |

| Healthcare | Biocompatible and non-reactive; ideal for surgical implants, wound care, and medical textiles. |

| Chemicals | Filters and separates substances; meets strict environmental rules and boosts efficiency. |

| Pharmaceuticals | Ensures sterile filtration and separation; supports regulatory compliance and product safety. |

| Food & Beverages | Filters and protects; helps meet safety standards and ensures product quality. |

You also see Ptfe Membrane in outdoor gear, such as waterproof breathable shoe linings and functional garments. The membrane keeps water out while letting sweat escape, so you stay dry and comfortable. In medical devices, expanded PTFE (ePTFE) membranes play a key role in surgical implants, wound care, dialysis, and infection control. These membranes meet strict FDA standards for safety and biocompatibility. Manufacturers follow rigorous quality controls and conduct clinical trials to ensure reliable performance in healthcare settings.

In water treatment, you use PTFE membranes to remove contaminants like organic solvents, dyes, heavy metals, and suspended solids. The membrane’s fine retention down to 0.01 micron helps you achieve high removal rates for micro-organisms and chemical pollutants. You rely on PTFE membranes for filtration of aggressive fluids, compressed gases, and bio-burden reduction in industrial and bioprocess environments.

Note: The growing demand for PTFE membranes in automotive, chemical, and healthcare sectors reflects their superior performance and compliance with strict regulations.

Maintenance and Replacement Guidelines

You keep your Ptfe Membrane working at its best by following proper maintenance steps. The membrane’s self-cleaning property lets rainwater wash away dirt, but you should clean it at least once or twice a year, especially in polluted areas. Use only mild cleaning agents approved by the manufacturer. Avoid harsh chemicals and high-pressure jets, which can damage the surface.

- Inspect the membrane visually every six months, focusing on seams, edges, and anchor points for signs of wear or damage.

- Schedule professional inspections every few years to check material integrity and structure.

- Repair minor tears or punctures quickly using specialized techniques to prevent further damage.

- Remove debris regularly and make sure drainage systems work well to prevent buildup.

- Address loose seams or connections right away to maintain strength.

- Handle the membrane gently to avoid scratches or punctures. Keep it away from sharp surfaces.

- Clean with a soft brush and mild detergent in lukewarm water. For tough stains, use a baking soda paste and rinse gently.

- Air-dry the membrane in a well-ventilated area, away from direct sunlight and heat.

- Store the membrane on a padded hanger in a cool, dry place. Avoid folding to prevent creases.

- Keep detailed records of all cleaning, inspections, and repairs to track the membrane’s condition.

You extend the lifespan of your Ptfe Membrane by following these steps. Regular maintenance helps you avoid costly repairs and ensures reliable performance. For complex cleaning or repairs, you should contact professional services to maintain safety and effectiveness.

Alert: Always consult the manufacturer for specific maintenance guidelines, especially if you use the membrane in extreme environments.

You benefit from Ptfe Membrane technology because it removes over 99.98% of fine particles and offers superior chemical resistance. Its durability and versatility support critical roles in environmental and medical fields.  When you understand these features, you select the right solution for your needs.

When you understand these features, you select the right solution for your needs.

FAQ

What makes PTFE membranes different from other filter materials?

You get superior chemical resistance and hydrophobicity with PTFE membranes. These features help you achieve high filtration efficiency and long-lasting performance in harsh environments.

Tip: PTFE membranes work well in both wet and dry conditions.

Can you use PTFE membranes for medical applications?

You can use PTFE membranes in medical devices. They offer biocompatibility, non-reactivity, and reliable filtration for wound care, implants, and sterile environments.

How do you clean and maintain a PTFE membrane?

You should use mild detergent and a soft brush for cleaning. Avoid harsh chemicals. Regular inspections help you spot damage early and keep your membrane working efficiently.

Post time: Aug-22-2025