You rely on PTFE Membrane technology to achieve exceptional filtration in industrial settings. With removal efficiencies exceeding 99.99% for particles as small as 0.3 microns, you experience fewer maintenance interruptions. In industries including chemical processing and food production, these membranes help you reduce downtime and lower operating costs.

Key Takeaways

- PTFE membranes offer exceptional chemical resistance, thermal stability, and hydrophobicity, making them ideal for reliable and efficient filtration in harsh industrial environments.

- These membranes achieve over 99.99% filtration efficiency for fine particles in both air and liquid purification, reducing maintenance needs and lowering operational costs.

- Using PTFE membranes with proper selection, regular cleaning, and maintenance extends filter life, improves energy efficiency, and supports sustainable industrial processes.

PTFE Membrane Properties and Industrial Selection

Key Performance Characteristics

When you choose a PTFE Membrane for industrial filtration, you benefit from a unique set of physical and chemical properties:

- Exceptional chemical inertness lets you use these membranes with strong acids, bases, and organic solvents without risk of degradation.

- Excellent thermal stability means you can rely on performance from -200°C up to +260°C, even in extreme environments.

- Hydrophobic surfaces prevent water from passing through, making these membranes ideal for gas filtration and waterproof applications.

- The expanded PTFE structure provides high porosity and mechanical strength, which boosts filtration efficiency and durability.

- Low friction surfaces help reduce fouling and make cleaning cycles easier, saving you time and maintenance costs.

- Long operational lifespan results from resistance to aging, UV exposure, and embrittlement.

You can also select membranes with controlled pore sizes, often ranging from 0.1 to 50 microns. This precise control ensures you capture fine particulates while maintaining high flow rates.

Criteria for Industrial Application

Industrial engineers use several criteria to select the right PTFE Membrane for each process. The table below highlights the most important factors:

| Selection Criteria | Description & Importance |

|---|---|

| Pore Size | Choose based on filtration needs, typically 0.1–50 microns for optimal performance. |

| Filtration Efficiency | Achieve >99.99% efficiency for sterile and cleanroom environments. |

| Temperature Tolerance | Operate reliably up to 260°C for high-temperature processes. |

| Chemical Resistance | Withstand harsh chemicals, oils, and solvents for long-term durability. |

| Hydrophobic/Oleophobic | Repel water and oils, preventing clogging and supporting moisture barrier applications. |

| Mechanical Support | Select with or without backing layers for added strength. |

| Surface Treatments | Tailor performance with additives or adhesive backings as needed. |

| Form Factor & Assembly | Available in sheets, discs, tubes, and custom shapes for flexible integration. |

| Industry Certifications | Ensure compliance with FDA, USP Class VI, and ISO standards for regulated industries. |

By matching these criteria to your operational and regulatory requirements, you ensure reliable and efficient purification in your facility.

PTFE Membrane in Air Purification

Filtration Mechanisms for Airborne Particulates

When you use PTFE Membrane technology in industrial air purification, you benefit from several advanced filtration mechanisms. These mechanisms work together to capture and remove airborne particulates efficiently:

- Surface Filtration: The smooth membrane surface traps fine dust particles on top, stopping them from passing through.

- Depth Filtration: A felt layer beneath the membrane holds larger particles, which protects the membrane and extends its life.

- Particle Size Exclusion: The microporous structure allows only clean air to pass, blocking particles above a certain size.

- Backflushing: You can clean the membrane by blasting it with compressed air or gas, which removes dust and restores filtration capacity.

- Chemical Resistance: The membrane resists corrosive gases and chemicals, so you get stable performance in harsh environments.

- Thermal Stability: High heat resistance lets you operate the filter at elevated temperatures common in industry.

- Low Friction Coefficient: Dust does not stick easily, which helps the membrane clean itself and maintain efficiency.

- Hydrophobicity: The membrane repels moisture, preventing clogging and ensuring steady airflow.

These mechanisms ensure that you capture a wide range of airborne contaminants, even in demanding industrial settings.

Efficiency Metrics and Operational Benefits

You can measure the performance of PTFE Membrane filters using several key metrics:

- Particle removal efficiency often exceeds 99.98% for particles as small as 0.3 microns and approaches 100% for 2.5 micron particles.

- Filtration efficiency curves show a characteristic ‘V’ shape between 10 and 300 nanometers, indicating strong performance across a broad particle size range.

- Pressure loss across the membrane remains low, especially when you use two membrane layers, which helps maintain energy efficiency.

- The hydrophobic nature of the membrane supports high filtration performance by preventing moisture-related fouling.

- Packing density and membrane dimensions, such as diameter and number of layers, influence overall efficiency and airflow.

- PTFE Membrane filters can reduce CO2 concentrations by more than 40% in ventilation systems, showing their practical value in air purification.

You also benefit from lower initial resistance compared to traditional glass fiber filters. This means your system uses less energy at startup. Composite PTFE media, which combine the membrane with efficient base materials, further reduce energy consumption by slowing resistance growth during dust loading. In some cases, you can achieve up to 59% energy savings at certain dust loads. Lower resistance growth and high permeability also reduce the energy needed for pumping air, which cuts operational costs.

PTFE Membrane filters maintain a low initial pressure drop, making them ideal for cleanrooms and other low dust load environments. As dust accumulates, the pressure drop increases predictably, but remains manageable in most industrial applications. Filters with PTFE nanofiber coatings keep airflow resistance low, even at high temperatures up to 280°C. This stability ensures reliable operation and long filter life.

| Filter Type | Particle Size Range (μm) | Filtration Efficiency (%) | Durability under Heat (100 °C) | Durability after IPA Exposure (%) | Pressure Drop (mmH2O) | Notes |

|---|---|---|---|---|---|---|

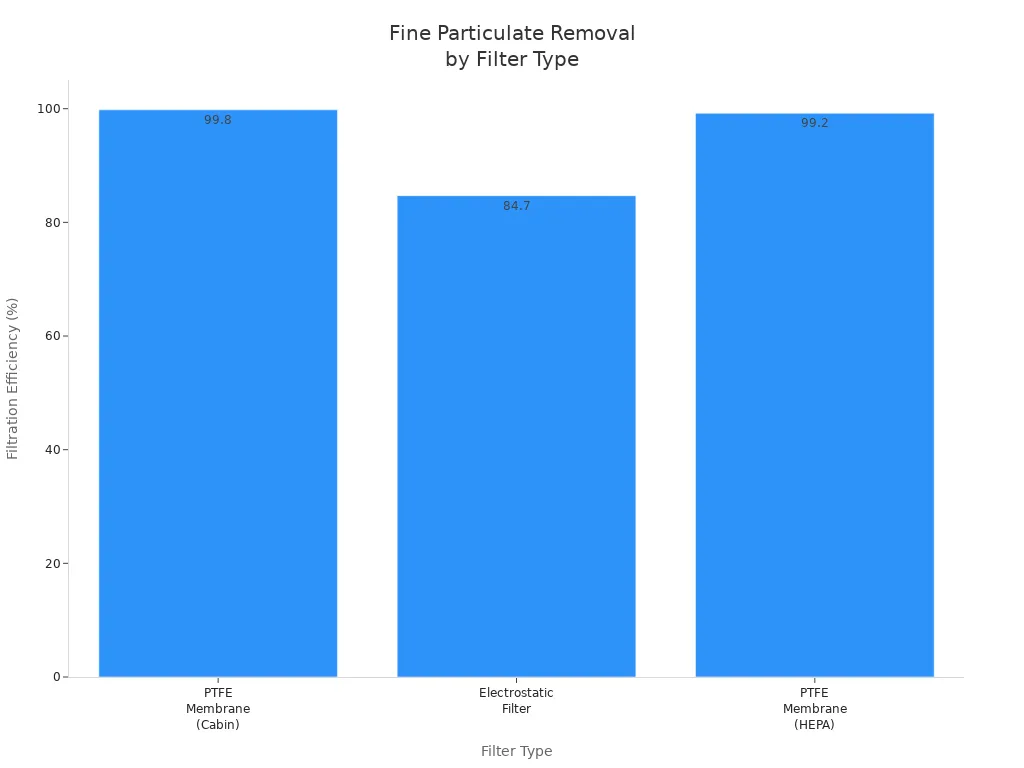

| PTFE Membrane (Cabin Filter) | 0.3 – 10 | >99 (e.g., 99.8% after cycles) | Maintains >99% efficiency | ~82.5 | ~2.9 | High stability after environmental cycles; superior to electrostatic filters |

| Commercial Electrostatic Filter | 0.3 – 0.5 | 84.7 at 100 °C | Efficiency drops significantly | ~41 | N/A | Efficiency degrades with temperature and solvent exposure due to loss of electrostatic charge |

| PTFE Membrane (HEPA Filter) | N/A | 99.2 | N/A | N/A | 13.98 | Slightly higher efficiency than cabin PTFE but with much higher pressure drop |

You can see that PTFE Membrane filters provide consistently high removal rates for fine particulates, even under challenging conditions. They outperform electrostatic filters, especially at high temperatures or after exposure to solvents, where electrostatic filters lose efficiency. PTFE Membrane filters also offer lower pressure drops than HEPA filters, which means better air permeability and energy savings.

Tip: To maximize energy efficiency and filter lifespan, consider using composite PTFE media and regular backflushing to control resistance growth and maintain optimal airflow.

Industrial Use Cases

You find PTFE Membrane filters in a wide range of industrial air purification systems. In one documented case, a PTFE membrane HEPA filter enhanced with melt-blown media operated in an HVAC system for 120 days. The filter maintained a high efficiency of 99.984% without any increase in pressure drop. This result demonstrates the filter’s durability and sustained performance in cleanroom and HVAC applications.

Manufacturing plants, air pollution control systems, and cleanrooms all rely on PTFE Membrane filters for their ability to remove fine particulates and maintain stable operation. Fab-Tex Filters and other industry leaders report successful use of these filters across multiple sectors, confirming their broad applicability.

You should always ensure the integrity of the membrane. Studies show that damage to PTFE membrane-coated filter bags can lead to significant leakage of fine particles, especially those smaller than 5 microns. Maintaining membrane integrity is essential for effective air purification and regulatory compliance.

PTFE Membrane filters deliver reliable, high-efficiency air purification in demanding industrial environments. Their unique properties and proven performance make them a preferred choice for modern air filtration systems.

PTFE Membrane in Liquid Purification

Mechanisms for Liquid Contaminant Removal

You rely on PTFE Membrane technology for advanced liquid purification because it uses several powerful mechanisms to remove contaminants. The most important mechanism is size exclusion. Here, particles larger than the membrane pores cannot pass through, so you achieve precise separation. The membrane’s surface charge also plays a role. If a contaminant has a similar charge to the membrane, it gets repelled, which increases removal efficiency for certain dissolved substances. Hydrophobic interactions further enhance performance. Hydrophobic contaminants tend to adsorb onto the membrane surface, which helps you remove trace organic compounds from water or process fluids.

In membrane distillation, PTFE Membrane technology uses volatility-driven vapor transport. Only volatile compounds pass through as vapor, while non-volatile contaminants stay behind. This method is especially effective for separating salts, metals, and organic pollutants from industrial wastewater.

| Mechanism | Description | Role in PTFE Membrane Contaminant Removal |

|---|---|---|

| Volatility-driven vapor transport | Separation based on vapor pressure differences; volatile compounds permeate as vapor. | Main mechanism in membrane distillation, rejecting non-volatile contaminants. |

| Charge exclusion | Electrostatic repulsion between membrane and charged contaminants. | Enhances removal of negatively charged compounds. |

| Adsorption (hydrophobicity) | Hydrophobic compounds stick to the membrane surface. | Improves removal of trace organic contaminants. |

| Size exclusion | Particles larger than pores are blocked. | Key for microfiltration and ultrafiltration. |

Note: You can select PTFE Membrane products with different pore sizes and surface properties to match your specific liquid purification needs.

Performance Data and Application Examples

You see outstanding results when you use PTFE Membrane filters in industrial liquid purification. These membranes deliver high removal efficiencies for a wide range of contaminants, including metals, salts, and organic matter. For example, PTFE Membrane filters with a 0.22 μm pore size can remove more than 99.8% of sulfate, aluminum, and iron from industrial wastewater. Even as you increase the feed temperature, removal rates remain high, and the average flux improves, allowing you to process more liquid in less time.

| Membrane Type & Pore Size | Feed Temp (°C) | Sulfate Removal (%) | Aluminum Removal (%) | Iron Removal (%) | Conductivity Removal (%) | Organic Matter Removal (%) | Average Flux (L/m²·h) |

|---|---|---|---|---|---|---|---|

| PTFE 0.22 μm | 50 | >99.8 | >99.5 | >99.9 | >99.8 | >85.7 | 11.90 |

| PTFE 0.22 μm | 60 | >99.8 | >96.7 | >99.9 | >99.8 | >85.7 | 12.86 |

| PTFE 0.22 μm | 70 | >99.5 | >92 | >99.9 | >99.5 | >85.7 | 14.29 |

| PTFE 0.45 μm | 50-80 | Comparable to 0.22 μm | Comparable to 0.22 μm | >99.9 | Comparable to 0.22 μm | >85.7 | 12.90-27.44 |

You benefit from stable flux and minimal fouling, even during extended operation. PTFE Membrane filters outperform many alternatives, such as PVDF membranes, by maintaining high throughput and resisting chemical attack. You can use these membranes in applications like media filtration, water softening, deionization, reverse osmosis, cooling tower filtration, and water process filtration. In membrane bioreactor systems, PTFE Membrane technology supports oil-water separation and advanced wastewater treatment, providing reliable performance in harsh industrial environments.

Post time: Jul-30-2025