You see industries transform as new uses for Eptfe Membrane spark innovation.

Here’s how demand grows across key sectors:

| Sector | Growth Drivers and Demand Evidence |

|---|---|

| Filtration | Environmental regulations, clean water, and air needs |

| Medical Devices | Cardiovascular care and surgical interventions |

| Electronics | Consumer tech and telecom expansion |

| Automotive | Electric vehicles and durable materials |

| Energy | Clean energy and battery systems |

| Construction | Industrial filters and protective textiles |

Advancements in ePTFE manufacturing now boost efficiency and drive product breakthroughs, helping you lead in a rapidly changing world.

Key Takeaways

- ePTFE membranes offer unmatched durability, breathability, and chemical resistance, making them ideal for diverse industries like medical, electronics, automotive, and construction.

- These membranes improve product performance by enabling advanced filtration, enhancing medical device safety, protecting electronics, and supporting clean energy solutions.

- The market for ePTFE membranes is growing rapidly, driven by innovation, sustainability efforts, and expanding applications, especially in Asia-Pacific and emerging sectors.

ePTFE Membrane in Manufacturing

Defining ePTFE Membrane

You may wonder what makes an Eptfe Membrane so special in modern manufacturing. This advanced material comes from expanded polytetrafluoroethylene, a process that transforms PTFE resin into a microporous structure. The journey of Eptfe Membrane began in the 1960s and 1970s, when manufacturers coated fabrics with PTFE for water and stain resistance. In the 1980s, the invention of expanded PTFE changed everything. Suddenly, you had access to breathable, waterproof fabrics that revolutionized outdoor gear. Over the years, manufacturers improved these membranes with multi-layer systems, advanced lamination, and even nanotechnology. Today, you see Eptfe Membrane in everything from smart textiles to high-performance filters.

The evolution of Eptfe Membrane manufacturing shows how innovation can unlock new possibilities for you and your industry.

Core Properties for Industrial Use

When you choose Eptfe Membrane, you gain access to a set of powerful properties that set it apart from other materials. These membranes offer outstanding waterproofness and breathability, with hydrostatic pressure resistance that exceeds 20 bar. Unlike microporous polyurethane, which loses performance over time, Eptfe Membrane stands strong through washing, weathering, and chemical exposure. You also benefit from superior durability and efficiency, as shown in industrial fuel cell applications:

| Metric | ePTFE Membrane | Traditional Alternatives |

|---|---|---|

| Peak Power Density | 724 mW/cm² | Lower |

| Mechanical Durability | High after 3000 cycles | Lower |

| Chemical Resistance | Excellent | Lower |

You can rely on Eptfe Membrane for long-lasting performance, even in the toughest environments. This material empowers you to create products that last longer, work better, and inspire confidence.

Emerging Applications of ePTFE Membrane

Advanced Filtration Solutions

You can see how Eptfe Membrane is transforming filtration across many industries. Its unique microporous structure allows air and moisture vapor to pass while blocking liquids and harmful particles. This means you get cleaner air and water, even in the toughest environments. In industrial air filtration, ePTFE-based filters now achieve efficiencies as high as 99.99%. These filters last longer and stay effective, even after repeated use. For example, composite HEPA filters with melt-blown media maintain filtration efficiency up to 99.984% for tiny particles, with stable pressure and longer life. You can rely on these membranes for cleanrooms, HVAC systems, and chemical processing plants.

| Industry | Application Examples | Documented Performance Improvements |

|---|---|---|

| Filtration | High-efficiency ePTFE filter membranes | Excellent retention; allows air and moisture vapor to pass while blocking liquids |

| Automotive | Protective vent membranes for electronics | Waterproof, breathable, chemical and temperature resistant; enhances electronics performance |

| Apparel | Waterproof breathable shoe linings, textile membranes | Waterproof, breathable; resists extreme temperatures and chemicals; improves comfort and durability |

| Medical | Cell culture membranes | Microporous polymer membranes ideal for cell culture |

| Agriculture | Composting covers for organic waste treatment | Improves organic fertilizer fermentation and waste management |

| Industrial Apparel | Flame retardant membranes | Fire protection, breathability, and durability |

| Electronics | Waterproof breathable protective vent membranes | Shields against water and oil, allows airflow, improves device reliability |

With Eptfe Membrane, you can set new standards for purity, safety, and efficiency in filtration.

Medical Devices and Healthcare Innovations

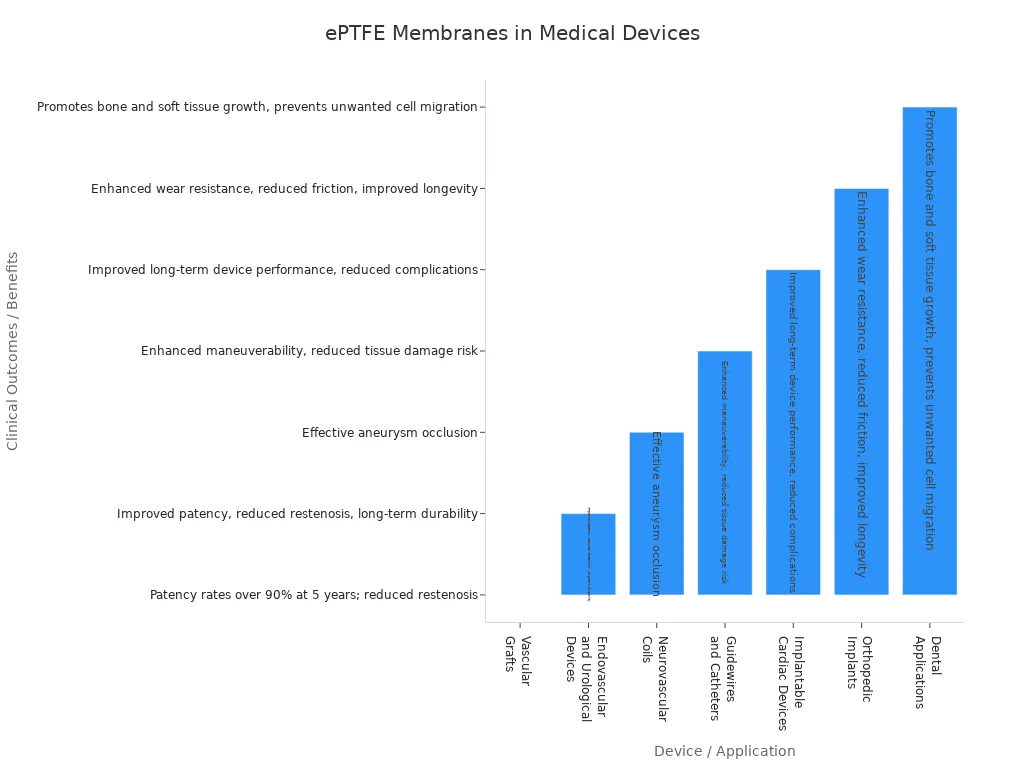

You help save lives and improve patient outcomes when you choose ePTFE membranes for medical devices. These membranes offer outstanding biocompatibility and durability. Vascular grafts made with ePTFE show patency rates over 90% after five years, reducing the risk of complications. Surgeons use PTFE-coated stents and neurovascular coils to achieve better results in cardiovascular and neurological procedures. Guidewires and catheters with PTFE coatings glide smoothly, lowering the risk of tissue damage. Dental and orthopedic implants benefit from enhanced wear resistance and promote healthy tissue growth.

| Medical Device / Application | Innovation / Use of ePTFE Membranes | Clinical Outcomes / Benefits |

|---|---|---|

| Vascular Grafts | ePTFE-based grafts with excellent biocompatibility and durability | Patency rates over 90% at 5 years; reduced restenosis |

| Endovascular and Urological Devices | PTFE-coated stents and vascular grafts | Improved patency, reduced restenosis, long-term durability |

| Neurovascular Coils | PTFE foam technology promoting rapid clot formation | Effective aneurysm occlusion |

| Guidewires and Catheters | PTFE coatings with hydrophilic properties to reduce friction | Enhanced maneuverability, reduced tissue damage risk |

| Implantable Cardiac Devices | PTFE coatings for biocompatibility and durability | Improved long-term device performance, reduced complications |

| Orthopedic Implants | PTFE-coated implants and joint replacements | Enhanced wear resistance, reduced friction, improved longevity |

| Dental Applications | PTFE membranes for guided tissue regeneration | Promotes bone and soft tissue growth, prevents unwanted cell migration |

Regulatory agencies like the FDA and ISO have cleared ePTFE membranes for long-term medical use, so you can trust their safety and effectiveness in critical healthcare settings.

Electronics and Semiconductor Protection

You protect sensitive electronics from water, dust, and oil when you use ePTFE membranes. These membranes equalize pressure, regulate moisture, and capture tiny particles, extending the life of your devices. Their microporous structure blocks contaminants while allowing airflow, which keeps electronics cool and reliable. You can find ePTFE membranes in smartphones, sensors, outdoor lighting, and telecom equipment. They provide IP67/IP68 protection, resist chemicals, and work in extreme temperatures from -250°C to 280°C. This means your devices stay safe and perform well, even in harsh environments.

- ePTFE membranes capture nano-sized particles and harmful contaminants in semiconductor manufacturing, reducing defects and improving yields.

- They allow moisture control and heat dissipation in electronics enclosures, which helps prevent failures and extends operational life.

- These membranes operate passively, so you save energy and support sustainability.

When you choose ePTFE membranes, you build electronics that last longer and perform better, inspiring confidence in every user.

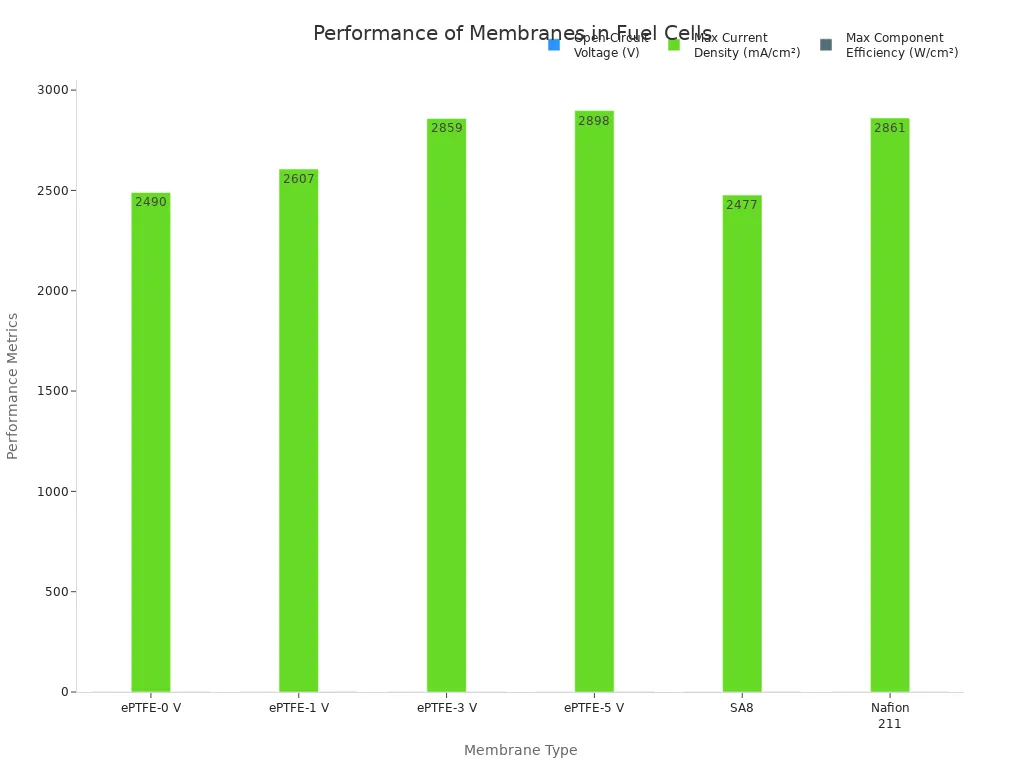

Energy Systems and Battery Technologies

You drive the future of clean energy by integrating ePTFE membranes into fuel cells and batteries. Their chemical inertness, porosity, and thermal stability make them ideal for harsh environments in energy systems. In electric vehicles, ePTFE membranes protect battery components and manage heat, supporting safe and efficient operation. Hybrid materials that combine ePTFE with nanomaterials like graphene boost conductivity and strength, which benefits aerospace and advanced electronics.

| Membrane Type | Open-Circuit Voltage (V) | Max Current Density (mA/cm²) | Max Component Efficiency (W/cm²) |

|---|---|---|---|

| ePTFE-0 V | 0.848 | 2490 | 0.80 |

| ePTFE-1 V | 0.847 | 2607 | 0.83 |

| ePTFE-3 V | 0.848 | 2859 | 0.89 |

| ePTFE-5 V | 0.847 | 2898 | 0.94 |

| SA8 | 0.747 | 2477 | 0.91 |

| Nafion 211 | 0.797 | 2861 | 0.93 |

With ePTFE membranes, you unlock higher efficiency, better stability, and longer life for fuel cells and batteries, powering a greener tomorrow.

Automotive and Transportation Uses

You can revolutionize automotive performance with ePTFE membranes. In cabin air filters, these membranes maintain filtration efficiency above 99% even under high temperatures and humidity. They outperform traditional filters, keeping air clean and fresh for passengers. In fuel cell vehicles, ePTFE membranes reinforce polymer electrolyte membranes, boosting durability and allowing thinner, lighter stacks. This means you get more power, less weight, and longer service life for both light-duty and heavy-duty vehicles.

When you use ePTFE membranes in transportation, you help create vehicles that are cleaner, more efficient, and ready for the future.

Construction and Building Materials

You build smarter, safer, and more durable structures with ePTFE membranes. These membranes prevent water infiltration, manage moisture, and improve energy efficiency in building envelopes. Architectural fabrics and roofing materials with ePTFE resist UV rays, weather, and fire, reducing maintenance and extending lifespan. PTFE-based coatings add water repellency and chemical resistance to construction joints and sealants, ensuring long-lasting protection.

| Construction Material/Application | Benefits of ePTFE Integration | Supporting Evidence |

|---|---|---|

| High-performance building membranes (e.g., GORE-TEX® building envelopes) | Prevent water infiltration and condensation; improve durability and energy efficiency; superior moisture management and air tightness | Gore’s GORE-TEX® technology adapted for buildings; reduces mold growth; improves energy efficiency |

| Architectural fabrics and tensile structures (e.g., stadium roofs, canopies) | Lightweight, durable, UV resistant, self-cleaning, weather resistant | PTFE-coated fiberglass fabrics widely used; excellent durability and resistance to environmental degradation |

| Roofing materials | UV resistance, weather resistance, self-cleaning properties, fire resistance | PTFE membranes and coatings extend lifespan and reduce maintenance costs; comply with fire safety standards (NFPA 285) |

| Protective coatings and additives | Enhance water repellency, chemical resistance, wear resistance | Daikin’s PTFE-based coatings and micropowders improve durability and performance of building materials |

| Insulation materials | Low thermal conductivity, fire resistance | PTFE’s thermal stability and flame-retardant properties contribute to energy efficiency and safety |

| Construction joints and sealants | Long-lasting protection against environmental factors | Gore’s PTFE-based gaskets and sealants provide durability under extreme weather and UV exposure |

By choosing ePTFE membranes, you create buildings that stand strong against the elements and deliver comfort and safety for years to come.

Technological Advancements in ePTFE Membrane

Nanotechnology and Material Science

You stand at the edge of a new era in material science. Nanotechnology now shapes the future of Eptfe Membrane, giving you tools to create membranes with unmatched performance. Researchers add nanoparticles and nanofibers to boost filtration selectivity and increase the flow of air or liquids. This approach lets you design membranes that respond to their environment, making them smarter and more efficient. By controlling the structure at the nano level, you can fine-tune flexibility, strength, and even electrical properties. These breakthroughs open doors for energy harvesting, advanced filtration, and medical devices that adapt to your needs.

Hybrid and Composite Membrane Materials

You can unlock even greater potential by combining ePTFE with other advanced materials. Hybrid and composite membranes bring together the best features of each component. For example, you might see membranes that blend ePTFE with nanofibers or special polymers. This fusion creates lightweight, flexible, and highly durable products. You gain membranes that resist oil, chemicals, and extreme temperatures. Custom solutions allow you to tailor wind resistance, breathability, and biocompatibility for each application. These innovations help you meet strict quality standards and reduce maintenance costs, especially in demanding industries like automotive and textiles.

Smart and Functional Coatings

You can transform the surface of ePTFE membranes with smart coatings. These coatings add new abilities, such as antimicrobial protection, UV resistance, and self-cleaning properties. By applying advanced lamination or surface treatments, you improve chemical resistance and make membranes more hydrophilic or oleophobic. In medical devices, these coatings reduce bacterial growth and improve tissue compatibility. In construction, they help membranes last longer and stay cleaner. With each new coating, you expand the possibilities for safer, more reliable, and more sustainable products.

Benefits and Challenges of ePTFE Membrane

Performance and Efficiency Advantages

You can achieve remarkable results with ePTFE membranes. These membranes deliver higher mechanical strength and longer operational lifetimes compared to traditional materials.

- Mechanical strength increases from 32.6 MPa to 44.0 MPa with ePTFE reinforcement.

- Peak power density reaches 0.279 W/cm² at 110°C and 25% relative humidity, which is 1.8 times higher than Nafion membranes.

- Improved glass transition temperature, hydration capacity, and proton conductivity boost performance.

- Enhanced chemical stability and durability ensure reliable operation over time.

You can trust these membranes to support demanding applications and help you reach new levels of efficiency.

Sustainability and Environmental Considerations

You help protect the environment when you choose Eptfe Membrane. Manufacturers manage chemical use carefully and often use renewable energy to reduce carbon footprints. The durability and longevity of these membranes mean you replace them less often, which lowers waste and resource use. Their chemical resistance also helps prevent leaks and spills in industrial settings. Some companies adopt ISO 14001 certification and Extended Producer Responsibility programs to further reduce environmental impact.

Tip: Recycling technologies for PTFE are still developing, so responsible disposal and sustainable practices remain important.

Regulatory Compliance and Safety

You can feel confident using ePTFE membranes in regulated industries. Many products meet certifications such as ISO 9001:2015 for quality and ISO 14001:2015 for environmental management. Some laboratory products even carry the ACT® Label for environmental responsibility. Companies like Gore work to eliminate harmful chemicals from their processes, aiming for safer and more sustainable products.

Current Limitations and Industry Hurdles

You may face some challenges with ePTFE membranes. High production costs and complex processing requirements can limit adoption, especially in cost-sensitive markets. Regulatory compliance can be demanding, with evolving standards and lengthy certification processes. Supply chain disruptions and inflationary pressures may also affect pricing and availability.

Note: Despite these hurdles, ongoing innovation and collaboration continue to drive progress in the industry.

Future Outlook for ePTFE Membrane

Industry Trends and Market Growth

You stand at the edge of a booming market. The demand for Eptfe Membrane continues to rise as industries seek cleaner energy and smarter solutions. The fuel cell segment alone is set to grow from $1.2 billion in 2024 to $2.5 billion by 2033, with a strong CAGR of 9.2%. You see this growth powered by new regulations, government support, and the push for lower carbon footprints. Asia-Pacific leads the way, especially with investments from China and Japan. Companies focus on digital transformation, AI-driven maintenance, and product customization to stay ahead.

| Aspect | Details |

|---|---|

| Market Size (Fuel Cell Segment) | USD 1.2B (2024) → USD 2.5B (2033) |

| CAGR (2026-2033) | 9.2% |

| Key Drivers | Regulations, subsidies, energy demand |

| Emerging Trends | AI, IoT, graphene composites |

| Regional Growth | Asia-Pacific fastest growing |

| Industry Focus | Fuel cells, aerospace, electronics |

Potential New Markets and Sectors

You can expect Eptfe Membrane to reach new heights in many sectors. Automotive, aerospace, chemical processing, and healthcare all show strong interest. The market for high-performance sealing and insulation could hit $500 million by 2025, growing at 6% through 2033. Smart tapes with sensors, biocompatible medical products, and sustainable production methods are on the rise. North America and Europe remain strong, but Asia-Pacific grows fastest thanks to rapid industrialization.

| New Sectors | Growth Drivers and Trends |

|---|---|

| Automotive | Electric vehicles, sealing, insulation |

| Aerospace | Lightweight, durable materials |

| Healthcare | Biocompatible tapes, medical devices |

| Electronics | Smart tapes, sensor integration |

| Food & Beverage | Safe, high-performance packaging |

Ongoing Research and Development

You help shape the future by supporting innovation. Researchers now use nanotechnology to boost membrane performance. They explore advanced manufacturing for better efficiency and uniformity. Many focus on improving biocompatibility for medical uses and developing custom membranes for filtration, gas separation, and biosensors. Sustainability matters more than ever, so you see greener processes and recyclable products. Digital twin technology and advanced modeling help optimize every step. Leading companies invest in new capacity and breakthrough ideas, driving the industry forward.

You play a vital role in this journey. Every step you take with Eptfe Membrane brings new possibilities for a cleaner, smarter world.

You see Eptfe Membrane changing industries every day. New uses drive rapid growth and inspire you to innovate.

- The market could reach $2.5 billion by 2033, with strong demand in Asia-Pacific and beyond.

- Companies focus on quality, sustainability, and digital engagement to lead the way.Stay curious and keep building the future together.

FAQ

What makes ePTFE membranes stand out in manufacturing?

You gain unmatched durability, chemical resistance, and breathability. These qualities help you create products that last longer and perform better in demanding environments.

Can you use ePTFE membranes in medical and food industries?

Yes! You can trust ePTFE membranes for medical devices and food processing. Their biocompatibility and purity meet strict safety standards.

How do ePTFE membranes support sustainability?

You help the planet by choosing ePTFE membranes. Their long lifespan and efficient performance reduce waste and energy use, supporting a cleaner future.

Post time: Aug-08-2025